YuMi Cobot

ABB YuMi Collaborative Robot

YuMi® – Creating an automated future together.

You and me.

In 2015 ABB introduced YuMi, the world’s first truly collaborative robot. The YuMi cobot was a game-changer and heralded a new era where people and robots safely and productively work side-by-side, without barriers. Collaborative robots are adept at adding flexibility to assembly processes that need to make small lots of highly individualised products, in short cycles. By combining people’s unique ability to adapt to change with robot’s tireless endurance for precise, repetitive tasks, it is possible to automate the assembly of many types of products on the same line.

Australis Engineering are an authorised ABB Robotics Value Partner – talk to us about implementing YuMi in your operations

Human – robot collaboration

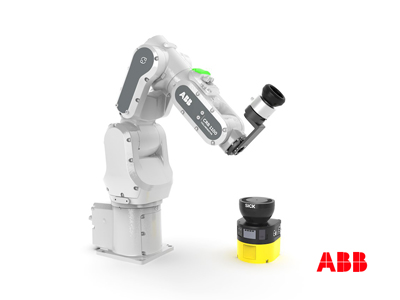

Innovative human – friendly dual arm robot with breakthrough functionality designed to unlock vast global additional automation potential in industry. YuMi® is designed for a new era of automation, for example in small parts assembly, where people and robots work side-by-side on the same tasks. Safety is built into the functionality of the robot itself. YuMi® removes the barriers to collaboration by making fencing and cages a thing of the past.

ABB’s growing family of YuMi robots is part of a suite of exciting collaborative automation solutions that help people and robots safely work closer together than every before possible.

ABB is adding a new member to the YuMi family, 7 axis YuMi, the smallest and most agile collaborative robot yet, making it easier than ever to put into production. The new 7 axis also opens up a world of flexible possibilities – for example a single-arm and a dual-arm YuMi could be combined to add a parts feed or inspection station to an assembly cell. Additionally, customer might want to have three or five YuMi arms in an application to improve the cycle time.

The entire YuMi family is designed to be easy to setup and use thanks to its intuitive lead through programming. That means that even people without specialized training or prior experience can successful use robots.

What tasks has YuMi been designed to carry out?

YuMi® is a collaborative, dual-arm Small Parts Assembly robot that includes flexible hands, parts feeding systems, camera-based part location and state-of-the-art robot control. It can collaborate, side-by-side, with humans in a normal manufacturing environment enabling companies to get the best out of both humans and robots, together. One of YuMi®’s unique features is its “inherently safe” design, allowing it to work alongside humans while reducing risks to acceptable safety levels.

Capable of handling anything from a watch to a tablet PC and with the level of accuracy that could thread a needle, YuMi® will radically change the way we think about assembly automation.

How does YuMi® differ from the competition?

Which benefits do dual-arms bring compared to a traditional robot arm?

Why YuMi®?

YuMi® is about “you” and “me” creating an automated future together.

YuMi® is “you” and “me”, working together to create endless possibilities. That’s YuMi®.

YuMi® meets the demands of a consumer market that is driving a need for greater flexibility in automated manufacturing head-on. For manufacturers, the market has changed the rules in ways that can be addressed effectively only by automation. The “new norm” of Small Parts Assembly is higher product volumes, shorter product life cycles, shorter lead times and a growing trend to customise goods – particularly electronics – close to final markets.

Other Cobots

For more information on collaborative robots available from Australis Engineering click HERE.

Video:

The following videos are courtesy of ABB:

YuMi Collaborative Robot

YuMi application video – making electronic parts

ABB Robotics Brochure

Click HERE to view the full ABB Robotics brochure with information about YuMi and other robots in the ABB range.

RELATED PRODUCTS