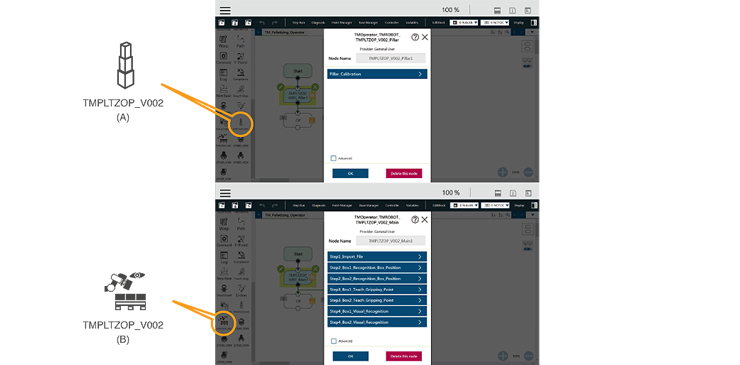

TM Palletizing Operator

ALL NEW Cobot Palletiser

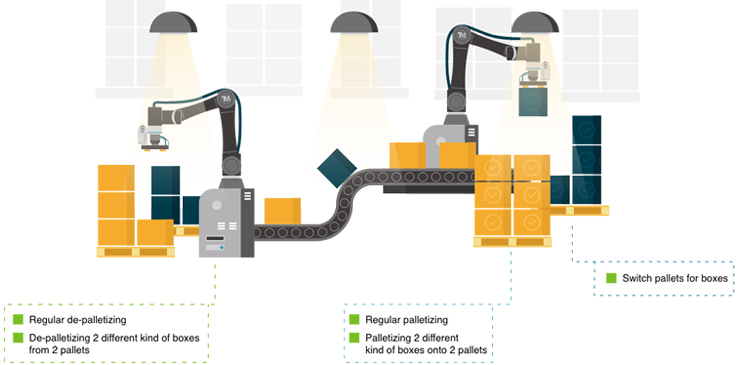

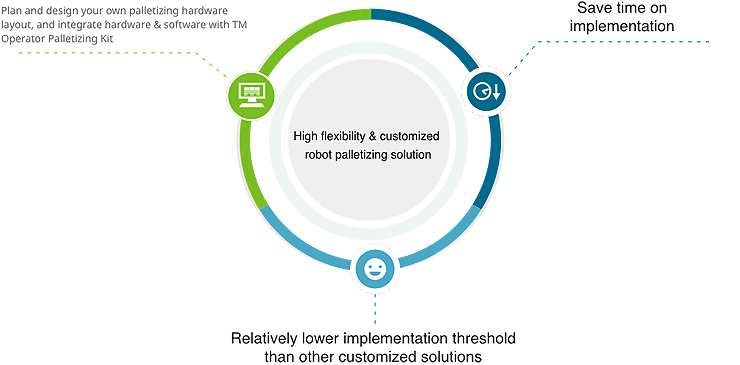

TM Palletizing Operator™ is an all-in-one solution exclusively designed for palletising automation. Techman palletising package includes built-in software that assists users to set up their palletising specifications quickly and can also carry out palletising simulations and collision tests beforehand. These benefits shorten the duration of palletising deployment from the usual six months to only just hours! This solution can be applied to many industries such as warehousing, logistics, food processing and manufacturing.

A highly reliable Robot Palletising Solution applicable to a Diverse Range of Industries

- 17 certified PL=d cell level safety functions

- Palletising speed of up to 7 boxes per minute (on a single pick, multiple picks will increase cycle times)

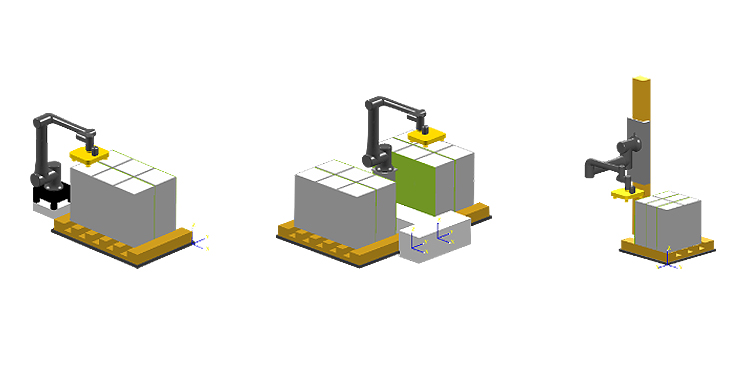

- Adjustable pillar with a maximum reach of 1200mm and a corresponded maximum stack height of 2325mm*

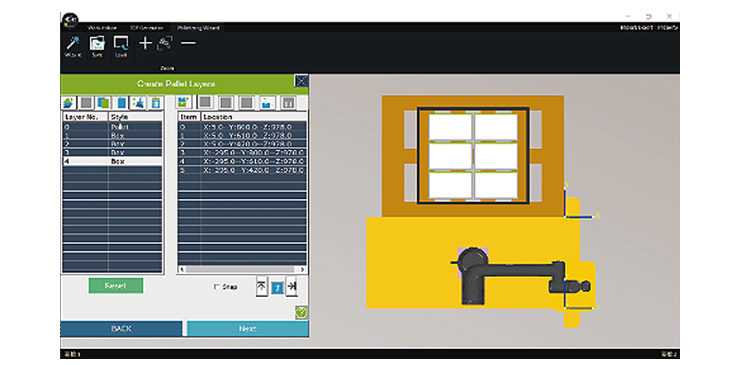

- TMstudio Palletizing Wizard™ – Simple palletising set up with simulation and collision detection

*Techman Robot offers 3 pillar strokes with different max. stack height, please see the specs sheet for more info.

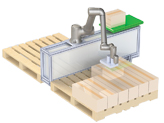

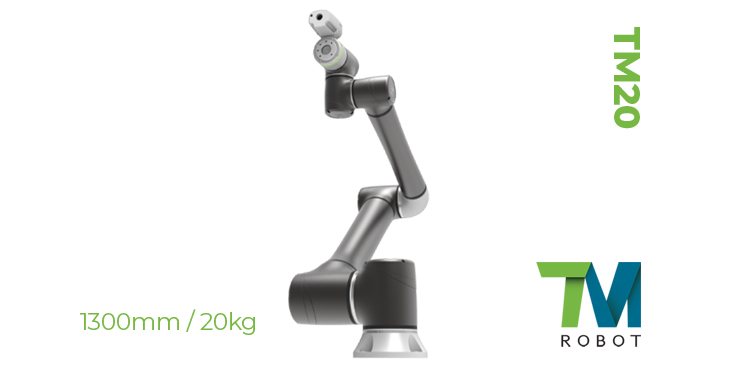

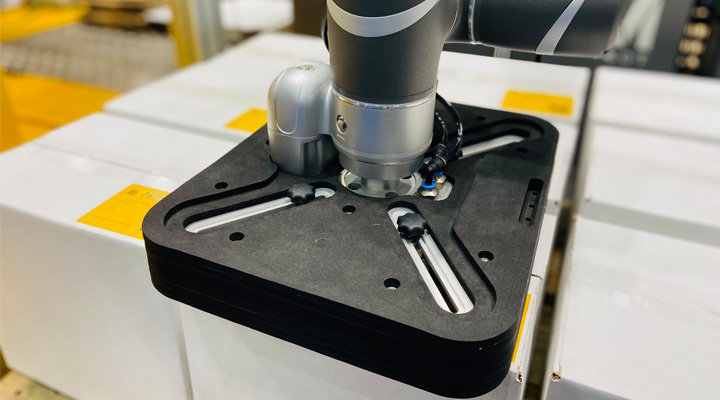

Either of the TM20 or TM25S (shown) collaborative robots are capable of palletising on a standard Australian Pallet (1165x1165mm)

Learn More

To find out more about the TM Palletizer Operator collaborative robot palletiser, please contact us.

Contact UsClick on the case study below to view

Watch this space for some future success stories …

Video

TM Palletizer Operator:

Here is a short video of the original TM Palletizer Operator featuring a TM12 cobot. (Note, use of a TM20 robot will increase the capabilities for payload and pallet dimensions)

TM Ai-Palletizer Operator:

Here is a short video of the TM Palletizer Operator using its onboard Ai.

RELATED PRODUCTS

PREVIOUS CLIENTS

Provide an Optimal Solution for Palletizing

Provide an Optimal Solution for Palletizing