Eva Robot

Eva – Low cost automation

Made in the UK

Eva is the simple, low cost robot from AUD$23,000+GST**. Engineered and manufactured in the United Kingdom by Automata from the ground up, Eva is designed to be lightweight, user friendly and accessible to all shop floor workers, retailers, students, academics – Eva is programmable in under 30 minutes.

With its controller integrated within the robot arm and base and weighing just 9.5kg, the Eva robot has a small footprint and is eminently portable, making it ideal for deployment across multiple tasks in your organisation.

Applications include machine tending, sorting, inspection and product testing, quality control checks, retail, research, education, health and medical and small parts product assembly. Automate your repetitive tasks to:

- Increase throughput and efficiency

- Reduce production costs

- Free staff from manual tasks

- Remove bottlenecks in production

Eva is available exclusively in Australia from Australis Engineering.

What’s Eva capable of?

1. Installation

Eva helps small businesses level the playing field

Its light weight and small footprint enable rapid changeovers and painless operation. It doesn’t require any special expertise to operate, nor does it need a control box or a teach pendant.

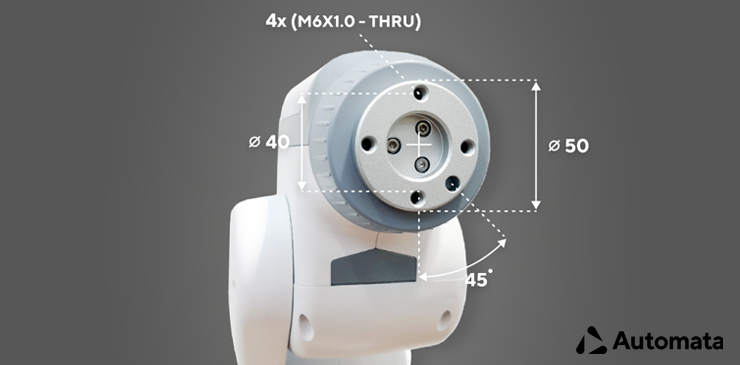

- Enclosure: IP20

- Base fixings: 4x M6 Screws or Bolts in a 132 x 132 mm square

- Tool fixings: 4x M6 Screws in a 40 mm ⌀ circle.

- Footprint: 160mm x 160 mm

2. Communication

Smart machines should simplify matters, not complicate them

Eva uses the technology you’re already familiar with to talk to you and your equipment.

- Programming: Use ethernet or Wi-Fi to connect your computer directly to Eva, or add it to your network just like a printer.

- Integration: Eva provides 24 V Industrial Logic: digital and analog inputs and outputs, totalling 32 pins.

3. Programming

People make all the difference, and Eva is designed to unlock their potential

Teach the robot by hand, then fine tune with Choreograph: software as intuitive as a smartphone app, running in your web browser.

- No need for a special computer

- No prior experience with robots necessary

- Expand Eva’s capabilities with the REST API or Python SDK

4. Performance

Traditional industrial robots are complicated, and overqualified for light automation

Eva excels at everyday processes, like loading machines, inspecting parts and precisely dispensing fluids.

- Speed: 750 mm/s (joint speed of 120°/s)

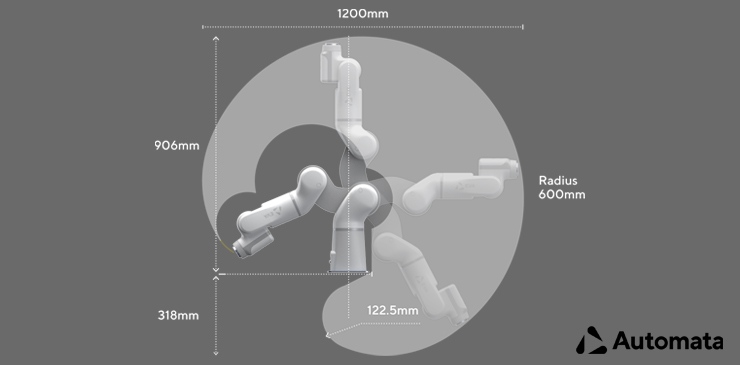

- Reach: 600 mm

- Payload: 1.25 kg

- Repeatability: ± 0.5 mm

How can a UK made robot be this affordable?

- Automata built their own powertrain, giving them complete control over Eva’s design.

- Automata took advantage of cutting edge prototyping technology to develop hardware at software speed.

- Automata focused on making Eva easy to install. They host demonstrations at their London HQ, and via video.

Australis Engineering are Automata’ exclusive Australian partner. With a wealth of robotics expertise, Australis can assist in providing you with a simple “robot in a box” for your team to integrate and programme or we can providing a fully integrated robotic system that’s cost effective and ready to be deployed within your business.

Your purchase of Eva includes:

01 – Phone support to help you with installation and troubleshooting

02 – A lifetime license to use Choreograph, our robot control interface

03 – Essential software updates to keep your robot performing securely

04 – Protection for a year with a full warranty, covering parts and labour

What’s in the box

- Eva – your portable, six axis robotic arm

- A mains power supply

- An emergency stop button

- Your user manual

- A brake release lever

Is Eva a cobot?

Conducting a risk assessment is still critical for cobots, regardless of where or how they are being used. As part of a new generation of lighter and safer robots, Automata’s Eva and its integrations are less dangerous to those working alongside it, but it should still be considered a piece of industrial machinery, not a cobot and should be treated accordingly with appropriate safety systems in place.

** Please note this price is subject to change without notification. Please contact us to confirm pricing at time of order.

Case Studies

The following case studies are all courtesy of Automata Technologies, the UK manufacturer of Eva!

Machine Tending Case Study: Qualitech, UK

Qualitech are a UK-based manufacturer of specialised metal components for products ranging from satellites to hairdryers. Their implementation of Eva uses a four cup vacuum gripper to safely and accurately pick up metal sheets and place them on a conveyor belt. Watch the video to hear how their story of working with Eva, and get some ideas about automating your own production line.

Product Testing Case Study: Nextgen, UK

Nextgen Technology is a multinational company headquartered in the UK. They provide automated testing and fault analysis services, helping their customers validate and launch new products in industries from automotive to smartphone development.

Nextgen were drawn to Eva for its RESTful API, ease of use and affordability. Today they’re using Eva to add physical interaction to their proprietary testing platform ATAM – allowing them to simulate real end user behaviour.

Inspection Demo: Conveyor belt and smart camera integration

In this application, the conveyor belt acts as a PLC. When a product is detected by the light gate, the conveyor belt stops, allowing one Eva to take a photo of the top of the can using a Cognex smart camera. Based on whether or not the logo on the can has been defaced, the second Eva then picks up the can and places it into the correct pass/fail lane, resuming the movement of the conveyor belt.

Sorting Demo: Machine vision for sorting

In this example, Eva is integrated with a smart camera (Cognex), which identifies the two different types of bottles – with and without a cap – and instructs Eva on the correct sorting bin to use. The pick-up points and coordinates of the small bottles are not pre-programmed, as evidenced by the manual shuffling that occurs towards the end of the video. Instead, Eva receives the coordinates of each bottle directly from the camera.

Videos

The following videos are all courtesy of Automata, the UK manufacturers of the Eva robot:

Eva – an introduction

Set-up Eva in just 15 minutes

Eva – personal programming

Sorting and Machine Vision Integration

Machine tending videos

Robot kitchen

Eva making a coffee

Eva Brochure

Click HERE or on the image above to view the Eva robot brochure.

Eva Specification Sheet

Our other robotic product lines

Selecting the right end of arm tool for your robot

One of the most important stages to ensuring success for your robot deployment is selecting the right end of arm tooling (EOAT) for the job. Here we take a look at the steps needed in scoping out what tooling is required for your specific processes, parts and environment.

What is end of arm tooling?

First, it’s worth discussing some of the terms commonly used when referring to the physical interface between a robot and the item being moved or worked on. Depending on the organisation or sector, terms including end effector, gripper, robotic hand or manipulator are often used interchangeably. For consistency, here at Automata we tend to use “end of arm tooling” as the catch-all term and we’ll take a look at definitions for some of the other commonly used terms below.

Why is end of arm tooling required?

Different jobs require different tools. Even processes that might seem identical at first glance may require very different solutions because of differences in environment or the way parts are presented. Both industrial and collaborative robots are designed to be adopted by a broad range of industries and applications and as such are generally not supplied with specific end of arm tooling. It is therefore up to the organisation implementing the robot (or integrator doing the work on their behalf) to assess the job to be done and select the most appropriate tools for the tasks at hand.

Where to start: understand the problem you’re trying to solve

The variations of end of arm tooling are broad. Options range from off the shelf tools from vendors such as Schunk or Zimmer, custom solutions built by integration specialists such as Active8 Robots or custom-made in-house, taking advantage of an organisation’s internal tooling capabilities and/or widely available equipment such as 3D printing. We share some examples of end of arm tools below.

Before looking at the options available, it’s important to start with understanding the problem you’re trying to solve and what you want to achieve. Start by answering the following questions:

- What is the weight of the items the robot will be moving?

- What are the shapes and sizes of the items to be moved? Are they uniform?

- What kind of surfaces do the items have? Are they hard, soft, porous, dry, oiled?

- Are the items delicate, unstable or need to be handled with care?

- Will you need a binary motion (open and closed only), or flexible gripping strokes?

- Do you have cleanroom, temperature or hygiene related requirements?

- How will the parts be presented to the robot? Will they be uniformly presented?

- What motion or process does the robot need to carry out? (for example: pick and place, button push, hook or scoop, torque or tighten, dispense or weld)

- Do you have a single process or item to be moved, different items at different times, or multiple on the same line or cell?

- Do you need need to exert any force as part of the process (for example: twist, screw, button press, polish)

- What level of accuracy is required?

- Are any additional sensors required?

- Will humans be working alongside the robot?

Common end of arm tools

Once you have scoped out the specific requirements and challenges associated with the parts to be moved or manipulated, you can move on to selecting the right type of tooling for the job. Broadly there are four common categories of EOAT.

Pneumatic grippers

Pneumatic grippers are mechanical devices typically with two or three fingers, powered by compressed air that pushes the jaws open or closed. They are extremely common in manufacturing and are used for a whole range of pick and place type applications. These types of tool are typically less expensive than electric grippers; however, unlike electric grippers, a pneumatic gripper will require an air line or air compressor to function. Pneumatic grippers also tend to be less precise than electronic grippers. On the other hand, they provide a more compliant grip with respect to their electric counterpart, and they are more forgiving to variations in shape and size of target objects.

Schunk MPG40 end effector for industrial robots

Electronic grippers

Electronic grippers, sometimes also known as servo grippers, are similar to pneumatic grippers but use electric actuation rather than compressed air to control the jaws of the tool. The benefit of this is they can be more precise than pneumatic grippers, with better control over speed, accuracy and force. The lack of need for compressed air can also mean a simpler set-up. However they tend to be heavier and more expensive than pneumatic grippers.

The Schunk EGP50 end effector for industrial robots

Vacuum grippers

Vacuum grippers – end of arm tools that use suction cups, rather than jaws, to pick up and move items – are extremely common across the entire spectrum of manufacturing businesses. Best suited to workpieces that are non-porous, clean and have a uniform surface for the cup to attach to, they can be lighter and more affordable relative to pneumatic and electronic grippers and are highly customisable. They require a negative pressure supply, which is usually obtained by placing a venturi tube (which comes in the form of plastic inline connection) at the end of a compressed air line.

Electromagnetic grippers

Electromagnetic grippers (and permanent magnet grippers) offer an alternative solution for ferrous metal parts. These types of tools are particularly useful for items that are not uniform and don’t have flat surfaces that might otherwise be challenging for grippers with jaws or suction cups. Particular care must be given to parts that might be sensitive to electromagnetic fields, such as delicate electronic components.

Specialist end of arm tools

In addition to these broad categories of end of arm tooling, there are also many types of custom and specialist solutions designed for specific applications such as spot gluing, welding, drilling, cutting, painting, spraying, buffing, scanning, sensing and vision.

Getting to success

If you’re installing the robot yourself, in addition to your chosen end of arm tool, you may also need to consider the following add-ons or accessories:

- An end plate (to attach the EOAT to the robot)

- Custom jaws or tooling (designed specifically to suit the workpiece)

- Cabling (to enable the robot to communicate with chosen tooling)

- An air supply (if using a pneumatic gripper or vacuum gripper)

- A vision system (if required for non-uniform parts or inspection)

- Additional safety requirements (if humans will be working with or near the robot)

RELATED PRODUCTS