simPAL Cobot Palletiser

The genius of simPAL®

Cobot Palletiser

The simPAL® Cobot Palletiser combines smart software and smart hardware to allow for a highly flexible, collaborative robot palletising solution. The simPAL cobot palletiser features the TM25S collaborative robot by Techman Robot . Utilising a collaborative robot on the simPAL Cobot Palletiser means we use minimal floor space – just 270mm wider than the pallet.

If your product is extremely lightweight, or you are using a smaller pallet (eg a Euro pallet), then a TM12, TM14, TM16 or TM20 cobots are also available and may be appropriate for certain palletising situations.

Palletise on an Australian Pallet

The simPAL Cobot palletiser with a TM25S collaborative robot is capable of palletising a standard 1165mm Australian pallet. The TM25S gives the simPAL Cobot Palletiser up to 25kg of payload capacity and over 1900mm of reach.

Palletise on a standard Australian Pallet (1165mm) such as a Chep or Loscam pallet

Cobot Palletiser with integrated vision system

By using a TM Robot collaborative robot, the simPAL cobot palletiser includes advanced vision-based QA which utilises the fully integrated 5MP camera on the TM Robot. simPAL is available with either a single or a double pallet configuration. To ensure operator safety, TM Robot’s collaborative robots have inbuilt safety features meaning the operate without the need for guards. This is both an important cost and space saving benefit and enables the simPAL Cobot palletiser to be deployed in the smallest footprint possible.

The simPAL Cobot Palletiser comes standard with a vacuum gripping pad which is suitable to a range of carton sizes and weights. Palletising rates of up to 8 cycles per minute∗ can be achieved for cartons/ boxes making this small footprint system the ideal replacement to manual palletising. ∗Note: Throughput and the gripper design are dependent on the product size and weight; carton or package dimensions; pallet pattern; the number of pallet layers required (finished pallet height) and product infeed speed and orientation. These variables will impact on palletising speeds. The actual palletising speeds (cycles/ minute) will be confirmed as part of our scoping process.

To ensure simPAL Cobot palletiser comes ready to palletise, the system is provided with an integrated infeed conveyor which can integrate with your existing conveyors (or we can supply a whole conveying system), so the entire machine is delivered 100% ready-to-go so installation is expedited, reducing downtime and cost. By using a cobot, the system allows excellent flexibility, speed of installation and ease of use. A typical simPAL cobot palletiser system can be brought to site, connected quickly and easily and be running within 2 or 3 business days (often faster when there are fewer products types being palletised).

More than just a cobot – simPAL Software is the heart of the solution

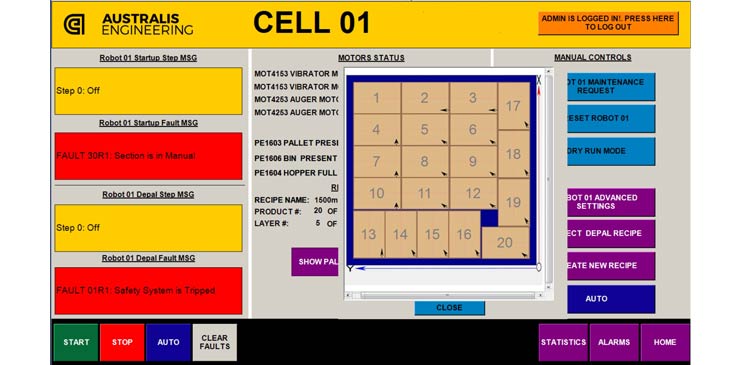

The heart of any simPAL system is our software. Designed in-house and building on over a decade of palletising experience, our simPAL software allows for new products to be introduced without needing to pay for expensive programming later on. simPAL Software provides long term future proofing benefits.

Without the need for complex programming, the user can easily generate new pallet patterns, enter new products and save new recipes. simPAL features an Automatic Pallet Generator that creates an optimised pattern or where there are multiple patterns available, allows the user to choose their preferred option. The user can also easily create their own custom pattern direct on the touch screen in a matter of moments. Coupled with the lead to teach capabilities of a Techman cobot and its own TM-Flow software, programming a simple pick and place with the simPAL Mini can be achieved in less than 5 minutes.

Need greater payload or speed?

The simPAL Cobot Palletiser is designed specifically for lighter weight products and modest palletising speeds. However if you require faster palletising speeds or your products exceed the payload of a cobot, we also offer our full simPAL robotic palletising system which uses an industrial grade multi-axis robot.

Contact Us

Click on the case study below to view

The simPAL Mini Cobot Palletiser was first launched at AUSPACK 2019 using a TM14 cobot. With the availability of the new TM20, cobot palletising just got serious! Watch this space for some future success stories …

Cobot palletiser video:

Here is a short video of the simPAL cobot palletiser using a TM14 cobot in action at the AUSPACK trade exhibition.

Click here to see more about the simPAL palletising system.

Click here to see more about the simPAL palletising system.RELATED PRODUCTS

PREVIOUS CLIENTS