Mech-Mind 3D Vision Systems

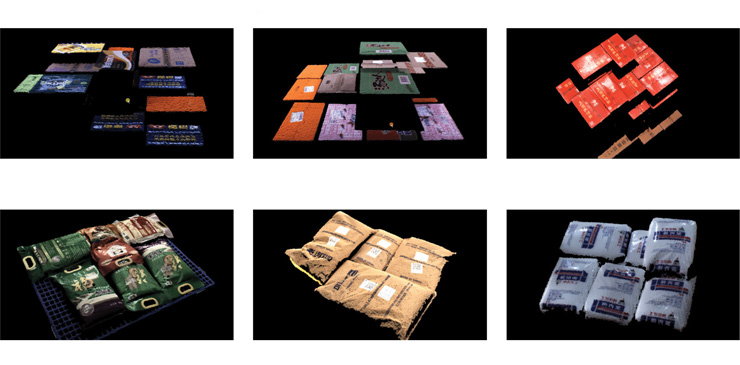

Thousands of Real World Cases

Mech-Mind robotics delivers complete and reliable solutions to real-world bin picking, order picking, depalletising, palletising, machine tending, assembly, gluing, high precision locating, high-precision measurement, defect detection and more.

Founded in 2016, Mech-Mind Robotics is a leading provider of 3D vision cameras, machine vision software and intelligent robotic solutions. On their mission to drive the ubiquity of intelligent robots, Mech-Mind has leveraged extensive technical strength to modernize manufacturing by breathing new life into industrial robots.

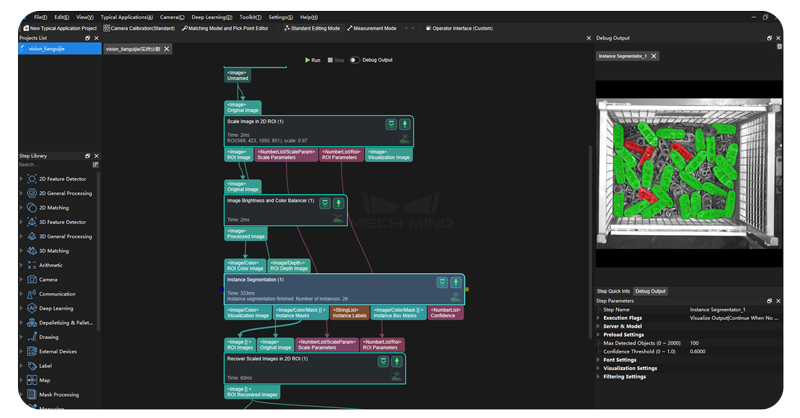

Mech-Mind has developed a full R&D and products portfolio including Mech-Eye industrial 3D cameras, Mech-Vision graphical machine vision software, Mech-DLK deep learning software, Mech-Viz intelligent robot programming environment, etc.

Exhibited at iREX 2022 in Tokoyo and 2020 CIIF in Shanghai, Mech-Mind has also been selected as 2019 Intel AI 100 Best Innovation Incentive Program and Microsoft Scaleup Member Enterprise.

So far, Mech-Mind has closed its Series C funding and raised a total of over $200 million. Backed by global top investors — IDG Capital, Meituan, Sequoia Capital China, Source Code Capital, Intel, Qiming Venture Capital, Delian Capital, China Growth Capital, etc., Mech-Mind has been one of the most funded robotics startups.

Australis Engineering are the Australian partners for the Mech-Mind product range and solutions.

High-performance industrial 3D cameras and intelligent platform software

Mech-Mind have developed a range of 3D Camera systems and software that integrate with robotics to revolutionise the way robots can be used and deployed. Their range includes:

- Mech-Eye Industrial 3D Cameras

- Mech-Vision Graphical Machine Vision Software

- Mech-Viz Intelligent Robot Programming Environment

- Mech-DLK Deep Learning Software

For full details and specifications of the Mech-Mind 3D Camera systems and intelligent software packages, click below.

Robotic solutions using 3D Vision and Artificial Intelligence

Mech-Mind offers a range of solutions to improve the efficiency and application of robotics in real-world situations. They have proven solutions for:

- Palletising and Depalletising

- Machine tending

- Piece Picking

- Bin Picking

- Assembly, Locating and Gluing

For full details and specifications of the Mech-Mind Robotic Solutions, click below.

Popular FAQs for Mech-Eye Industrial 3D Camera

Q1: What is an industrial 3D camera?

An industrial 3D camera is a camera used in industrial applications which can capture objects and reconstruct them from a three-dimensional image. It’s been increasingly used in diverse industries, especially in manufacturing and logistics.

Q2: How does the industrial 3D camera work?

Usually, industrial 3D cameras work with robots to complete various industrial tasks like picking & placing, assembly, inspection, measurement, etc. Industrial 3D cameras can be mounted on the arm or end effector of robots to capture and collect 3D data of the target objects, which is fundamental for robots to execute further steps like pick & place, load & unload, etc.

Q3: What are the main features of Mech-Eye industrial 3D camera?

Mech-Eye 3D camera features high precision, fast processing speed, and high-cost performance.

Mech-Eye industrial 3D camera has full model options, which cover a wide range of industrial applications with diverse requirements on working distance, accuracy, ambient light resistance, etc.

Q4: What are the most used applications of Mech-Eye Industrial 3D Camera?

Mech-Eye 3D cameras can be used in almost all common robot applications, including bin picking, machine tending, palletizing & depalletizing, automated piece picking, assembly, etc.

Contact UsPalletising and Depalletising

Core Advantages

|

|

|

|

High Cost-Effectiveness |

Robust Recognition |

Intelligent Path Planning |

| The price is only half to the same type of typical products. | Thanks to powerful AI algorithms, robots can handle cases or sacks with patterns, tapes, express bills, and reflective films.

Deformed sacks, and sacks with wrinkles and patterns can also be well handled. |

The built-in path planning algorithm guarantees the movement of robots is precise and collision-free. |

|

|

|

|

Plug and Play, Easy to Use |

Support Various Pallet Patterns |

Automated Palletising |

| A visualised interface can simulate the robots’ movement with only one click.

The code-free programming enables a low threshold for operators to deploy. |

With an extra-wide view, it can well handle all common pallet patterns (such as the dimension of 1.2*1.2*1.8m). | Vision-guided robots can palletise automatically according to the sizes and weights of cases. It also supports mixed-case palletising of objects. |

Specification

| Accuracy | 1 mm @ 3 m, 3 mm @ 3 m |

| Distance | 1500mm – 3500mm |

| Speed | Up to 900 cartons/hour. |

| Objects | Support closely packed cases or sacks;

Support angled cases or cartons; Support objects with patterns, tapes, and express bills. |

| Robots Brands | Can be adapted to various mainstream robot brands, such as ABB, KUKA, YASKAWA, Kawasaki, Rokae, Peitian, Techman Robot, Estun, etc. |

| Calibration | Self-calibration |

| Service | Personalised solution

Staff training Fixture design |

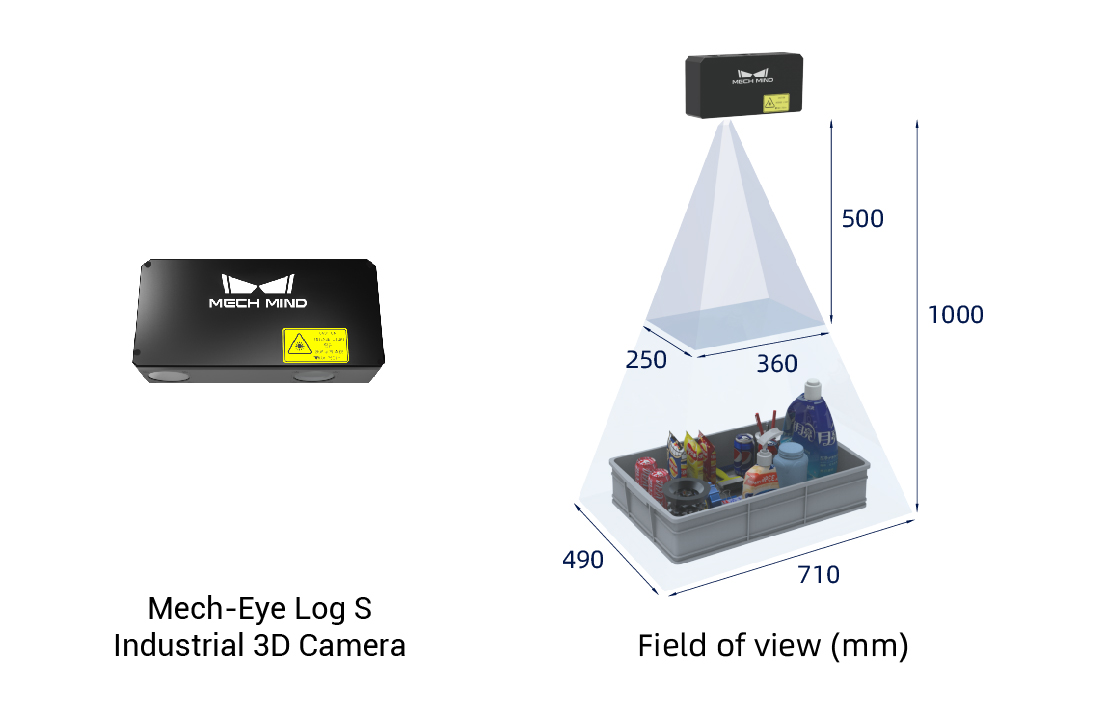

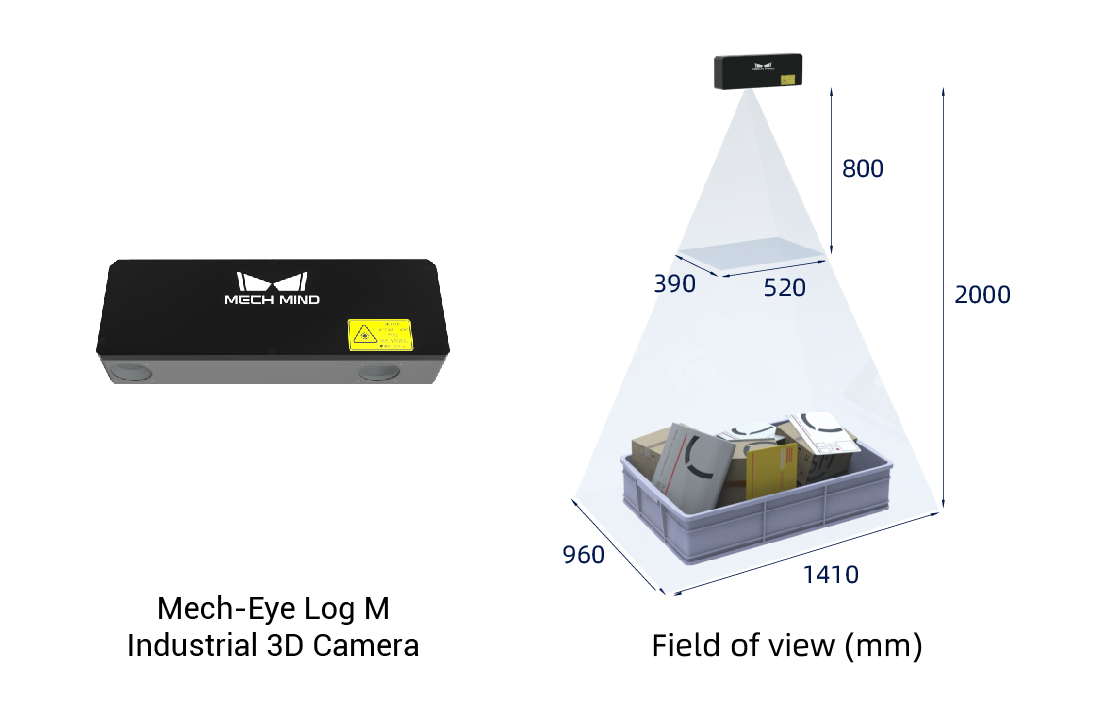

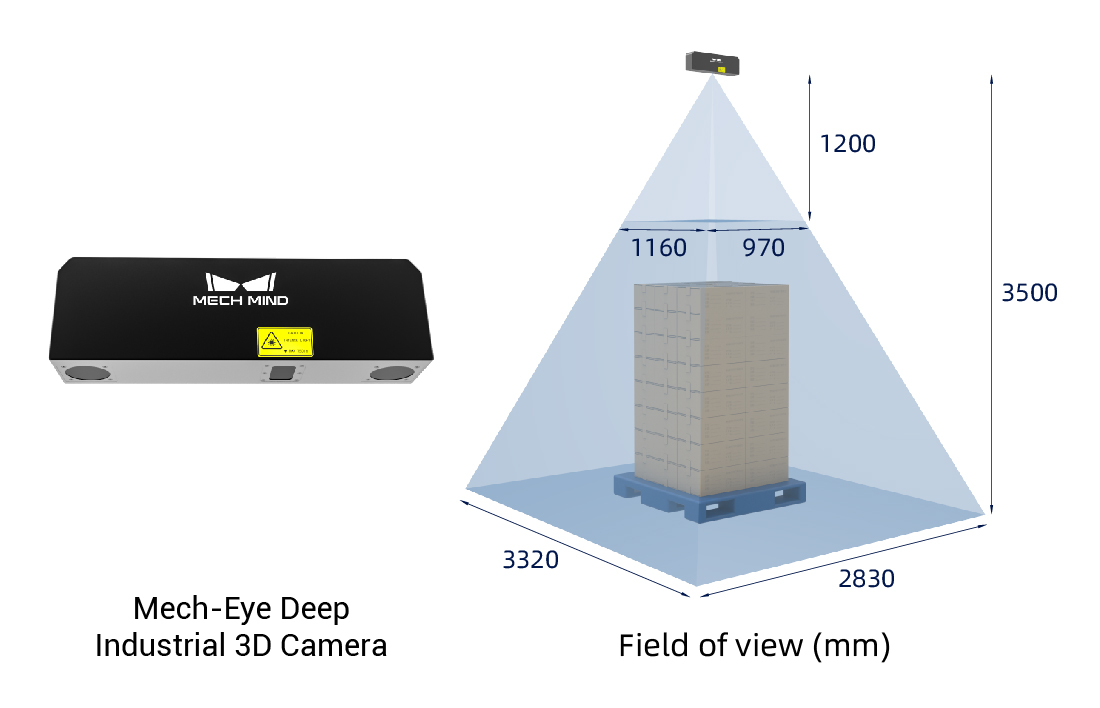

Camera Introduction

Mech-Eye Deep

- A deep depth of field

- Applicable for various common pallet patterns

Mech-Eye Log S

- Built-in ambient light resistance

- A large field of view

- Fast scanning speed

- Easy integration

- The 3D vision system allows Mech-Eye to easily recognise various objects that are with dark surfaces and complex structures.

Mech-Eye Log M

- High precision

- Ambient light resistance

- Can recognize various objects with dark surfaces and complex structures

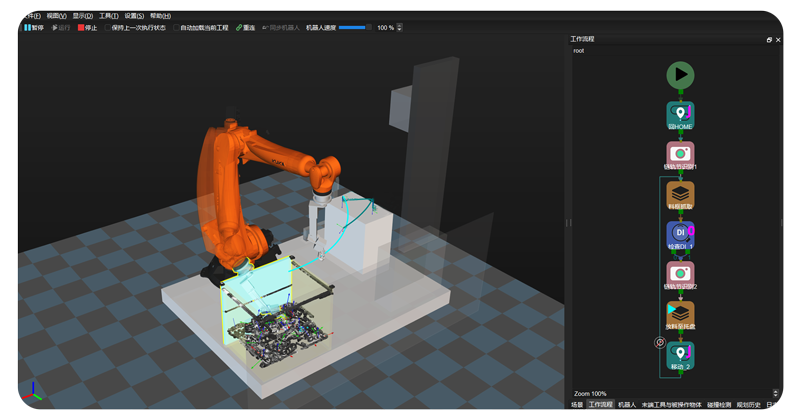

Bin Picking

Guided along by the powerful 3D vision system, the robots can recognize randomly-piled materials, even those with dark or reflective surfaces and complex structures, and then pick them up from deep bins accurately without damaging the components.

Core Advantages

|

|

|

| High Cost-Effectiveness | Powerful Algorithms | Intelligent Path Planning |

| The price is only half to the same type of typical products. | AI algorithms enable robots to accurately pick up various objects (including complex-structured metal parts with dark or reflective surfaces). | The built-in path planning algorithm guarantees the movement of robots is precise and collision-free. |

|

|

|

| Plug and Play, Easy to Use | Seamless Integration with the WMS System | |

| A visualized interface can simulate the robots’ movement with only one click.

The code-free programming enables a low threshold for operators to deploy. |

Seamless integration with the WMS system allows robots to pick goods on demand. |

Specification

| Speed | Single cycle time can reach 3s |

| Objects | Support objects in different sizes and shapes (including randomly stacked tiny objects, complex-structured metal parts with dark or shiny surfaces, etc.) |

| Robot Brands | Can be adapted to various mainstream robot brands, such as ABB, KUKA, YASKAWA, Kawasaki, Rokae, Peitian, Techman, Estun, etc. |

| Calibration | Self-calibration |

| Service | Personalized solution;

Staff training; Fixture design. |

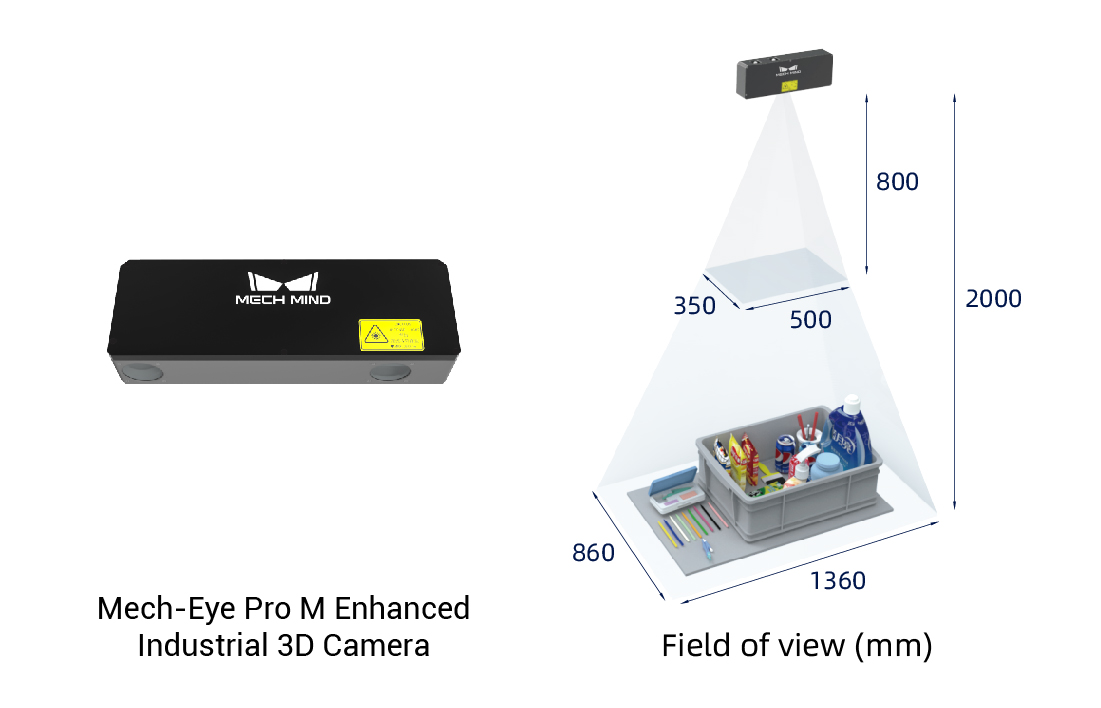

Mech-Eye Pro M Enhanced

- High scanning speed

- High precision

- A big field of view.

- Support various objects (including objects with black or considerably reflective surfaces)

Video

The following videos are courtesy of Mech-Mind:

How AI+3D Robots Fuel the Rise of Smart Manufacturing

Vision Guided Mixed Carton Palletising

AI+3D Vision-Guided Machine Tending Applications

How AI+3D Robots Ushering a New Era of Logistics Automation

Parcel-Picking with Mech-Mind Robotics

Guide your robot with Mech-Mind Robotics!

RELATED PRODUCTS

PREVIOUS CLIENTS