Automating your business with Robotics

Given the current economic climate, with severe labour shortages, rising input costs and significant delays within supply chains, many businesses are turning to robotic automation in their facilities to help overcome some of these challenges. Why? Because its never been simpler (or cheaper) to deploy a robot in your business.

Deploying a robot can help your business increase production volume or improve quality, all while lowering costs. But, those that are yet to leap into the world of robotic automation might be concerned with the cost, especially with so much uncertainty around at the moment.

Below we help review the costs that should be considered before taking advantage of the long term benefits that automation can provide.

What is the Value of Robotics?

Implementing robotics is one of the smartest investments any business can make but especially now with severe labour shortages across Australia coupled with rapidly increasing wage costs. Despite this landscape, your customers still want their products delivered faster, with improved quality, a smaller environmental footprint and of course – cheaper! Robotics can help you achieve these results before your competitors can do it first.

Deploying robotics allows your business to do the job of a highly skilled worker, often for a fraction of the cost. Why? Robots don’t take meal breaks. They don’t catch COVID or take sick leave. They don’t need a holiday or get injured and cost workers compensation. While yes they have some operating costs and will require some occasional maintenance, often those costs are lower than the ongoing costs for a human worker. Robots are ideal for repetitive tasks that otherwise tie-up skilled workers and prevent them from using their expertise on higher value tasks. In the right application, robots can operate to multiple shifts, even 24 hours a day, seven days a week. Moreover, robots can resolve several different manufacturing needs and can be customised to perform a very wide range of tasks, from pouring liquids, to stacking and palletising, to carton forming, quality inspections, machine tending, sanding, screwing, soldering, welding, assembly and so much more! Often multiple applications can be achieved with just one robot.

Robotic automation works for a range of industries too. While traditionally modern robots have been well utilised in manufacturing industries, they are also suitable in retail or customer facing environments, warehousing, food and beverage, pharmaceutical and medtech, additive and extractive fabrication, automotive, aerospace and mining. In fact, there are even robots in the entertainment sector.

Modern robots can be deployed almost anywhere and for a multitude of applications. One of the keys to achieve this diversification of deployment is that many robotic solutions are becoming easier and faster to customise and the advent of collaborative robots makes them safer and easier for non-experts to operate and even undertake new programming.

What to consider before deploying a robot?

While there are numerous benefits to investing in automated robotic solutions, and the future cost-savings might be clear, for businesses that are new to robotics, you might need to understand the cumulative upfront costs. To make this investment as profitable as possible, consider the following factors when engaging in budgeting and strategic planning efforts for your future robotic automation needs:

1. Cost of Robots

One of the most common questions asked when considering whether to invest in robotics is, “what is the robot’s upfront cost?”. Your Board, CEO, CFO, Manager or the Owner wants to know the actual cost of deploying a robotic system. While it is only one pillar of the investment equation, it is usually the primary budgeting factor because it may require the highest upfront financial resources.

Although the total cost can depend upon how many robots you need and what you’re using them for, the cost for a robotic solution can vary depending on the:

- application,

- speed of your process,

- safety requirements required,

- physical size (LxWxH) of your product,

- weight of your product,

- type of packaging of the product (bag, carton, pallet, drum etc),

- product’s composition (glass, plastic, cardboard, powder, metal, timber, raw foods etc),

- environment it operates in (hot, dusty, cold, hygienic),

- footprint or size of area that you have to deploy the robot,

- whether off-the-shelf options exist, or is significant customisation required, and

- is supplementary equipment required to support the robotic system, eg new conveyors, packaging equipment or pallet handling equipment.

To give you some indications of costs (and putting aside micro-robots with payloads under 1kg), a:

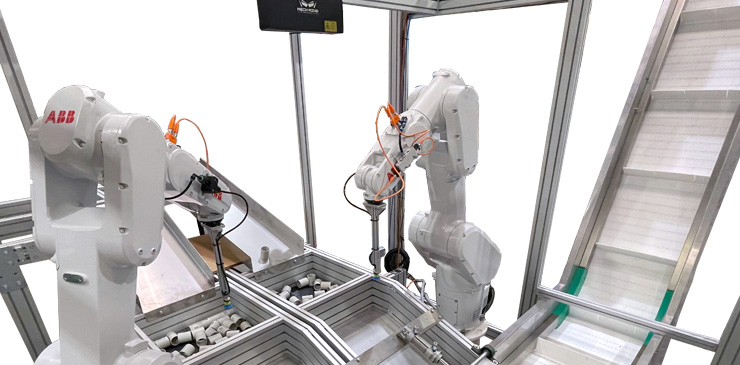

- Basic palletising system using a full size industrial robot such as an ABB IRB460 and with a basic Australian standard safety system, starts from AUD$200,000 but can rise rapidly depending on speed and weight considerations.

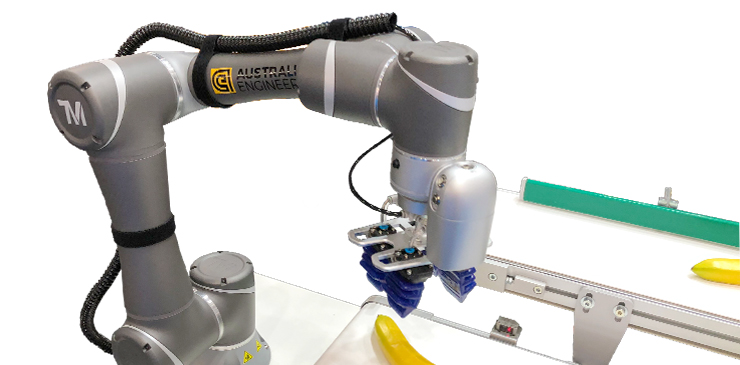

- Simple collaborative robot pick and place type application starts from AUD$50,000 which would include a cobot such as a Techman Robot TM5, and a basic vacuum end effector (gripper).

- Robot machine tending application using a collaborative robot may start from around $65,000 including the robot, end effector, base and a basic, small conveyor or basic parts jig.

*Cost estimates accurate at date of publication, but are subject to change

While the above costs are only an approximation (and costs are changing rapidly in this high inflation environment – so its worth checking current costs), it’s an important consideration when considering robotic automation. Fortunately, there are some options to help offset the upfront costs of ownership, such as:

- Operating Lease

- Tax incentives such as the Instant Asset Write-Off

- Government Grants – these are often highly competitive and won’t be suitable for most robotic deployments

Let’s explore the Operating Lease option for a moment. An Operating Lease allows you to assign costs to your operating (OPEX) budget not your capital equipment budget (CAPEX). Why? Because the Operating Lease bundles both the capital equipment cost and other costs like maintenance and training into the one package.

An Operating Lease permits your business to use the equipment being leased, but doesn’t provide up-front ownership. This provides balance sheet relief for businesses as the lease is considered an operating expense, and is not recorded as an asset! But the good news is, an Operating Lease can still be structured to allow your business to take full ownership at the end of the lease period for very little money – even just $1.00.

However, Australis are not the leasing experts. We work with a highly regarded company called Business Growth Finance who provide all the formal advice and establish the lease if that’s the best option for your business.

2. Lead time and commissioning

The upfront cost is only one component of deploying an automated robotic solution. In the current COVID environment, one of the key challenges to deploying a robot is lead time. World-wide shortages of computer chips, prolonged sea and air freight passage and on-going global disruptions are all contributing to acute shortages for automation products and robots are unfortunately not immune. However, the good news is that Australis has well established partnerships with two of the global robotics powerhouses – ABB Robots and Techman Robot.

Lead times for industrial robots are constantly changing. But as a rule of thumb, allow a minimum of 18 weeks from order for the robot to arrive at Australis. Note, some robot models are taking significantly longer, so please discuss how lead times may affect your project.

Lead times for the much smaller collaborative robots are also under pressure. But most models are available for dispatch around 8 weeks from order. Again, these timeframes are constantly changing, so please check with us about how your project might be affected.

The only good news about the longer lead times for delivery of the robots is that it generally allows sufficient time to finalise the layout, mechanical and automation design of your customised solution, meaning that final fabrication can commence more quickly once the robot arrives at Australis.

The final lead time factor to take into account is Commissioning time. It is important to appreciate that a customised robotic solution may take several weeks to properly commission – but this is normally only required if your business has high product diversity or complexity. In many cases, your customised robotic solution can be commissioned in 1 or 2 days (for a cobot) or 4 to 5 days for an industrial robot. Again, its important to understand that each application is different and commissioning doesn’t mean there is zero production, we normally switch to “wet” commissioning using actual product very quickly and so in many situations, you will continue to produce albeit at a slower rate while commissioning is completed.

For businesses producing a high diversity of product, the availability of your product for testing will also impact final commissioning timeframes – if a certain product is produced infrequently, that has obvious impacts to the final commissioning of a robotics system.

3. Operating and Maintenance Costs

Maintenance and operating costs are two of the other considerations of the robotics equation that you or your decision makers may want to consider.

The great news is that robots are among the most reliable and easy to maintain pieces of industrial equipment that are available. Robots generally operate seamlessly for weeks, months and even years at a time with only minimal routine maintenance required.

When robots are appropriately maintained, repaired, and serviced, their production life can be extended by many years before needing to be replaced. You may consider using a preventative maintenance checklist or keeping your equipment on a regular maintenance schedule to avoid any significant issues that could stop production or cut into your profits. For larger robots it might be as simple as a yearly oil change and to check any wear on articulation joints. For collaborative robots its generally a basic check of the joints and servos inside the robot arm. Alternatively, for businesses less experienced in robotics, Australis can design and deliver an affordable maintenance program for you – we can even add these costs to an Operating Lease (see above) to make the ownership equation even simpler.

Luckily, many robotic automation users quickly understand the cost savings for operating a robot compared to human workers and soon notice that maintenance costs are lower than staff operational and on-costs.

Are there operating costs? Yes, there are some daily operating costs for your robot. Robots are electrical and so there will be some energy costs to operate the robot. In some cases you may require an end effector that requires compressed air to actuate and so the energy cost to operate the end effector may also need consideration.

End Effectors or Grippers

That opens the discussion to end effectors. There is enormous range and brands of end effectors from leading suppliers such as OnRobot, Robotique, Schunk and many others. In some cases, some end effectors may use consumable parts – think suction cups, silicon skirts (eg. the skirts on OnRobot’s “Soft Gripper” in the image hereabouts), foam pads, sanding discs, even screw driver bits, solder or welding rods. Each application will be different and there are many robotic solutions that won’t require consumables at all, so talk to Australis about the potential for any consumables costs for your customised robot solution.

4. Return on Investment or ROI

There is no doubt that the leap into robotics needs to be worthwhile financially for your business. The most important question usually asked by the higher ups will be – “when can I see a return on our investment?” While your key decision-makers may want to see an ROI within two years, it’s imperative to consider all the ways your robotic solution will work for you over the long haul, and we routinely see some outstanding ROI results, from as little as 6 or 12 months in some applications (especially where a collaborative robot is an appropriate solution).

Let’s say you purchase a medium-sized robot for material handling applications. Taking into account the energy requirements, you can approximate the cost to operate per hour. When you compare that cost to human labour, think direct costs such as wages, superannuation, payroll tax, FBT, training, downtime and other on-costs; but also consider other in-direct costs such as inconsistent/ poor quality control, inconsistent quantity control (e.g. your customer pays for 20kg but is actually getting 22kg) and variable output rates (eg lower outputs on a Friday compared to other days of the week). When you compare these human costs to the prolonged operational lifespan of a robot, the differences are often staggering, and the economics can become overwhelmingly positive for deploying a robot.

What about the current labour shortages being experienced across virtually every sector of the Australian economy? If you are finding it hard to recruit or retain people, or their wages are increasing quickly, you can deploy your customised robot to perform the repetitive, mundane, risky or low skilled tasks in your business – like stacking boxes. You can then take those existing staff who you have already invested in and have accumulated corporate knowledge and deploy those staff to the more human-centric tasks – quality control, dispatch, order placement, systems management, maintenance or even customer facing roles. You can get the best of both resources. A robot that never rests and is fast and consistent every day of the year, plus workers who know your business and can be better utilised in more critical parts of the business. Automation does not mean placing people on the unemployment queue!

In addition to the input cost savings, let’s take into account the production gains. A robotic system can permit Lights Out production, or two or three shifts of production at a much lower cost than using workers. Robotic automation can also increase your product output as the robot may be able to work faster and given it doesn’t take a break it is quite easy to increase your output significantly. One of our clients reported that their labour cost per unit of product produced reduced by 33% following the deployment of a basic automated palletising system and, as a result has reduced the total unit cost of their product by 5%. As a result the client’s labour requirements across two shifts have reduced by 2 people (who were deployed in more high value roles). Moreover, there were intangible benefits including that the automated system has removed a Work Health and Safety manual handling problem from the workplace which in the short term improved WHS and in the medium term reduced workers compensation insurance premiums and payroll tax.

Calculating ROI – an example

The following is a basic calculation for ROI. To perform the ROI assessment you will require the following data:

- Total system cost: This is calculated by determining the robotic automation system cost. You may also want to consider using a multiplier of between 1.5 – 3.0 to account for additional one-time costs associated with deployment, such as if your site requires any other electrical, ancillary equipment or facility upgrades to support deployment of the robot.

- Robot utilisation: Determine how many shifts per day each robot will operate.

- Current labour costs without a robotics system: Calculate the annual labour costs by estimating the number of operators whose tasks will be replaced by the robot. This total will determine the labour savings of purchasing the automated system.

- Anticipated labour costs with a robotics system: Decide how many operators you will need to operate, service, and maintain the system.

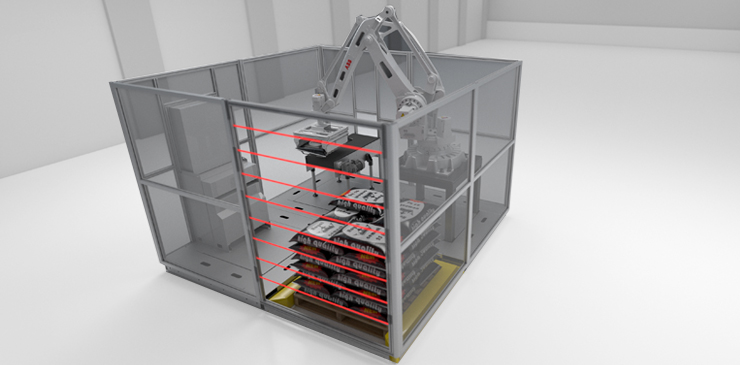

Let’s create a hypothetical example. Say you want to purchase a basic Robotic Palletising system for $200,000 that will be utilised for a single shift per day using one operator. Something similar to the example below of Australis’ simPAL palletising system:

Total robotic system cost: AUD$200,000

Current labour costs without robotics system: $225,000 (3 operators at an annual wage and superannuation cost of $75,000 – or approximately $35/hr)

Anticipated labour costs with robotics system: $75,000

Labour savings: $150,000 (Current labour costs of $225,000 less the $75,000 anticipated labour for the new robotic system)

ROI: AUD$50,000 in the first year ($200,000 – $150,000)

At that rate of $50,000 ROI per year, you can expect to drive returns after 16 months of purchasing the system. Should you move to a “lights-out” operation, or a second shift, then ROI would be expected to improve further and potentially be achieved in less than 12 months. Although you will still want to consider the variable costs, such as operating expenses, maintenance and consumables these are offset by savings that you can anticipate from improved product quality and consistency, faster throughput, improved employee morale and improved workplace safety.

If the business also continues to deploy additional process automation of its operations, the savings will continue to overtake the initial investment costs. With an improved understanding of the anticipated ROI of robotic automation, you should be able to justify the investment to company stakeholders effectively.

Conclusion

Australis Engineering are experts in smart robotic automation. We understand that the cost to automate your business is a critical consideration for the decision makers of any business. These decision makers need to be confident that by deploying a robotic system, it will be a successful and profitable venture from the beginning and into the future. Our team of experts knows how important it is to have efficient, robust, and reliable robotic equipment that can benefit your bottom line for years to come.

No matter the industry or complexity, we can create custom automation solutions that fit your unique needs. Contact us to learn more about deploying cost-effective robotics for your business.