simPAL ROBOTIC PALLETISER

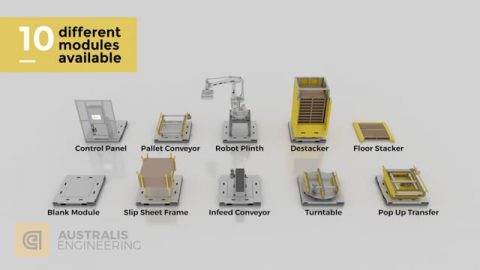

simPAL is a revolutionary approach to robotic palletising. simPAL combines Australis' proprietary palletising software with a touchscreen HMI and a modular palletising system including an industrial multi-axis palletising robot to create a modular robotic palletising system which can grow with your business.

HYGENIUS FOOD GRADE CLEAN CONVEYOR

Hygenius is a food grade conveyor designed to reduce flat surfaces, cracks and crevices where food and bacteria accumulate. It is very fast and easy to prepare for cleaning and is fully wash down ready - just 2 minutes to prep for cleaning. Best for raw meat, poultry, smallgoods, fruit & veg, seafood, pet food and dairy.

TM25S COBOT PALLETISER

Need a palletiser, but don't have much space? A Cobot Palletiser offers lower investment costs with the benefit of a small footprint. Our TM25S Cobot Palletiser offers 1, 2 or 3 pallet position and easily palletises a standard Australian pallet (1165 x 1165mm). The TM25S cobot palletiser has a load capacity of 25kg and 1902mm reach.

COBOT CARTON ERECTOR

A Cobot Carton Erector is best suited to multi-format carton erecting and is best with 2 or 3 blank carton magazines, but can also operate with just 1 carton magazine. Depending on carton size, the Cobot Carton Erector can form up to 6 cartons per minute. In the video we show a TM12 collaborative robot with 12kg payload and 1300mm reach.

TM COBOT PICK & PLACE

Techman Robot's collaborative robots (TM Series) have an inbuilt vision system making them highly adaptable for many applications. The vision system allows for many pick & place applications such as demonstrated in this video where the TM5-900 cobot sees a banana regardless of its orientation on the conveyor and can successfully pick the banana using its 5MP camera.

TM COBOT SOLVES A PUZZLE

The TM5 collaborative robot by Techman Robot has an integrated vision system that it uses to identify puzzle pieces and match them to the puzzle board. Demonstrating that similar applications such as machine tending, pick & place or parts assembly can be easily achieved with a TM cobot and its inbuilt 5MP camera.

TM5 ROBOT CASE STUDY

Designed Mouldings are a leading injection moulder, specialising in the pharma and medical areas. They used an OnRobot VGC10 gripper and a Techman Robot TM5 collaborative robot in their production process to achieve a tripling of production, reduction in waste to 2% and a 6 month ROI. Watch the video of this case study.

TM5 ROBOT BARISTA

Techman Robot's TM5 collaborative robot operates as a coffee barista's assistant at the Seven Mile Coffee Roaster's at Manly Vale on the northern beaches of Sydney by utilising an OnRobot RG2 gripper to grip the portafilter and insert to an autotamper and then present this to the barista.

TM COBOT SORTING

Australis recently attended the Taipei Automation exhibition 2019. As Australian distributors of Techman Robot collaborative robots, we were excited to see so many new applications for these amazing cobots with their integrated vision systems. Techman Robot collaborative robots are ideal for packing and packaging applications such as this sorting application using pick and place and the integrated vision system.

AUTOMATICA 2018

In June 2018, Australis sent a group of staff to the Automatica trade exhibition in Munich, Germany - the world's largest exhibition for robotics and automation equipment and technology. Our video shows some of the incredible highlights of the show, including amazing technology from ABB, Highwin, Comau, Fanuc, SEW and more.

ROBOTIC BAG PALLETISER

This project featured an automated robotic bag palletising system which included a multi-axis industrial robot that palletises bag of concrete and also picks and places a layer pad. The gripper head was custom designed by our automation engineers. The whole system includes an infeed conveyor, out feed pallet conveyors and a full safety and controls system. Components were upgraded for the harsh, dusty environment.

TECHMAN ROBOT – COBOT CAPABILITIES

Techman Robot manufacture the TM series of collaborative robots. These cobots are capable of a diverse range of applications as showcased in this introductory video. Capabilities include palletising, pick & place, bin picking, assembly, screwing, deburring, soldering and more. Australis are Australian distributors of Techman Robot collaborative robots.

SLAT CONVEYOR SYSTEM

Our video features a slat chain conveyor system including lay down conveyors and spiral conveyors for a food production facility. Slat chain conveyors are available in multiple configurations to suit different products and operating environments. Curves, transfers, inclines, declines and numerous other options are available.

SINGLE FILER CONVEYOR

Our Single Filer Conveyors are designed to take empty bottles from a mass flow environment, for example off a depalletiser or accumulation conveyor into a single file to enable filling or labelling. Our single filer which is suitable for round or square glass bottles or bottles with a taper and is also suitable for PET bottles.

CARTON CONVEYOR SYSTEM

Our automated carton conveyor system featured belt conveyors, powered roller conveyors, a continuous platform elevator and a modular belt conveyor with a tight radius curve. The system is fully PLC controlled and features two HMI's, allowing operators full control and overview of the system.

ROYAL AUSTRALIAN MINT COIN SYSTEM

Australis successfully delivered a multi-million dollar turnkey project at the Royal Australian Mint that provided a new circulating coin manufacturing facility including MES, robotics, AGVs, conveyors, bucket elevators, packaging equipment, vision systems, coin counters, coin inspection equipment and warehousing.

3 PALLET POSITION PALLETISER

Mini Palletiser (MLP12) featuring 3 pallet positions for multiple product types. Our MLP12 is capable of palletising boxes, cartons or bags. The video shows the MLP12 running at AUSPACK in demo mode (approx. 30% normal operating speed). Single and double pallet versions are also available.

HIGH SPEED DIVERTER

A customised high speed diverting system for boxes, actuated by a servo-motor and ball screw for higher accuracy. Its capable of forming 4, 5 or 6 rows of product. Incorporates a powered modular belt conveyor to handle boxes operating at 70 metres/ minute. Customisable for most box sizes. Diverter infeeds to a case packer.

- 1

- 2