Train Wheel Handling

Train Wheel Handling Equipment

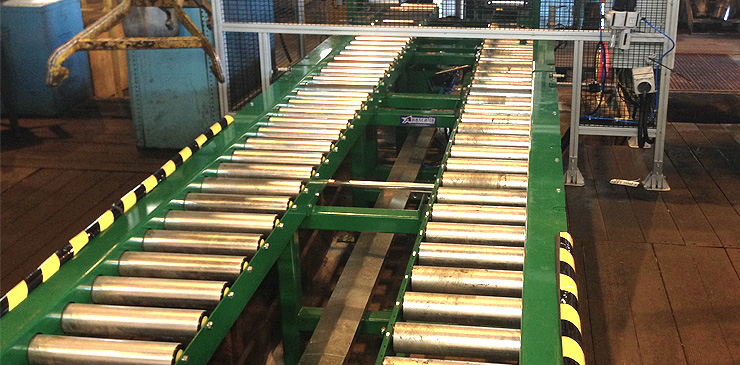

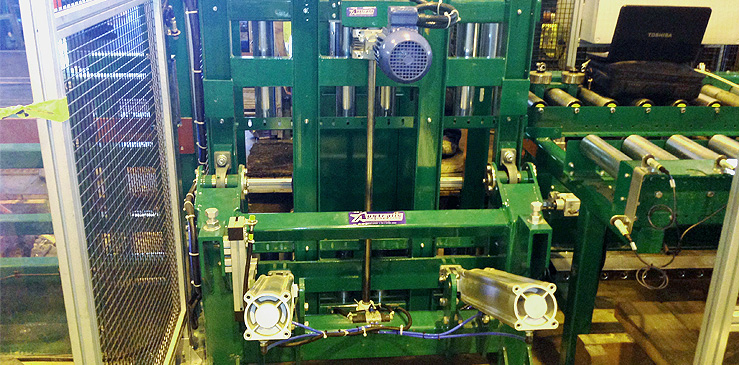

Australis have successfully delivered special purpose machinery to assist with the maintenance and quality inspection of used train wheels for a major service provider in the NSW railways system. Using our existing knowledge of conveying systems and by utilising our industrial automation skills, Australis designed a special purpose conveyor and tilting mechanism that allowed the train wheel maintenance contracted to insert used train wheels into the system, safely lock the train wheel in place and then tilt the wheel safely in order to undertake a maintenance and quality check prior to redeploying the wheels into the railways rolling stock fleet.

The key challenges of this custom-built materials handling system were to design equipment that could handle the weight of solid steel train wheels and to safely lock these into place to allow for safe inspection by the operators. Moreover the system had to be manufactured to cater for a large range of train wheel diameters. Our Engineering Team successfully considered all of these issues and utilised a modified version of our pallet conveyors and a fully customised tilt and lock-mechanism to provide a safe and efficient solution to inspect the used train wheels.

Watch the VIDEO on the video tab to see the train wheel handling system operating.

With a strong track record in the engineering design, R&D, proto-typing, manufacture and commissioning of special purpose equipment, Australis welcomes the opportunity to discuss how we can improve your manufacturing throughput and reduce your input costs by implementing a customised steel bar handling solution.

Contact UsClick on the case study below to view

A case study is not currently available. Please check back again soon

Please see our short video of the Train Wheel Handling system during factory acceptance testing.

Click here or on the brochure image to view more information on our Materials Handling Solutions.

Click here or on the brochure image to view more information on our Materials Handling Solutions.

RELATED PRODUCTS

PREVIOUS CLIENTS