TM25S Cobot

TM25S AI Collaborative Robot

The Future Is Here – NEW S-Series collaborative robots

Native AI engine + Robotic arm + Vision system

Using cobots for Manufacturing, Warehousing and Processing tasks is the key to unlocking efficiency. Improve the overall performance of your production and assembly lines with automation solutions like our AI Cobot series, a family of collaborative robots with built-in vision systems and AI technology. Our cobots help to establish a harmonious work environment where humans and machines collaborate and excel.

Embrace the Future of Automation

Techman Robot collaborative robots are designed for a diverse range of tasks, suitable for operations of any scale. They are simple to install, program, operate, and can be easily scaled. TM’s cobots provide a cost-effective, flexible, and safe automation solution that is suitable for manufacturing and processing businesses of all sizes including small and medium businesses. Techman Robot can help you achieve smart manufacturing and process handling and be the competitive edge you need for greater productivity.

TM25S – Enhanced Payload and Reach Capabilities

Applications

Palletising, Pick & Place, High-Volume Packaging, Machine Tending and more

The TM25S is the first dedicated cobot with the capability to palletise without complicated secondary mechanisms onto an Australian 1165mm pallet. With it’s 25kg payload, the TM25S will be a game changer for cobot palletising in the Australian market

Payload

TM25S – 25kg payload and 1900mm reach

AI Cobot – Faster

- Unleash the Power of Advanced Vision

- The S series cobot is equipped with an integrated vision system featuring advanced AI technology that elevates your manufacturing operations

- Pair it with our TM AI+ Training Server solution to unlock the full potential of the cobot’s capabilities and take your vision application to new heights

Techman Robots are fitted with a vision system that has quickly challenged the stereotype of a traditional industrial robot. This built-in intelligent vision system utilises a 5MP camera and is a huge technological breakthrough for TM Robot, producing the perfect integration of the vision system with the collaborative robot hardware and software. You no longer have to face complicated visual components like before, nor waste the time spent in researching an unfamiliar robotic field. Now, all you need is a TM Robot, which can do everything for you.

The TM Robot vision system has received recognition from many robot vision manufacturers. The functions it provides include shape matching, totem pairing, object position, image enhancement mode, bar code and QR code identification; colour recognition and OCR which are all easily configured from the integral robot design toolbox.. These diversified functions have all been integrated in the control system of the TM Flow Robot. Only by setting the steps, you can design the robot’s tasks.

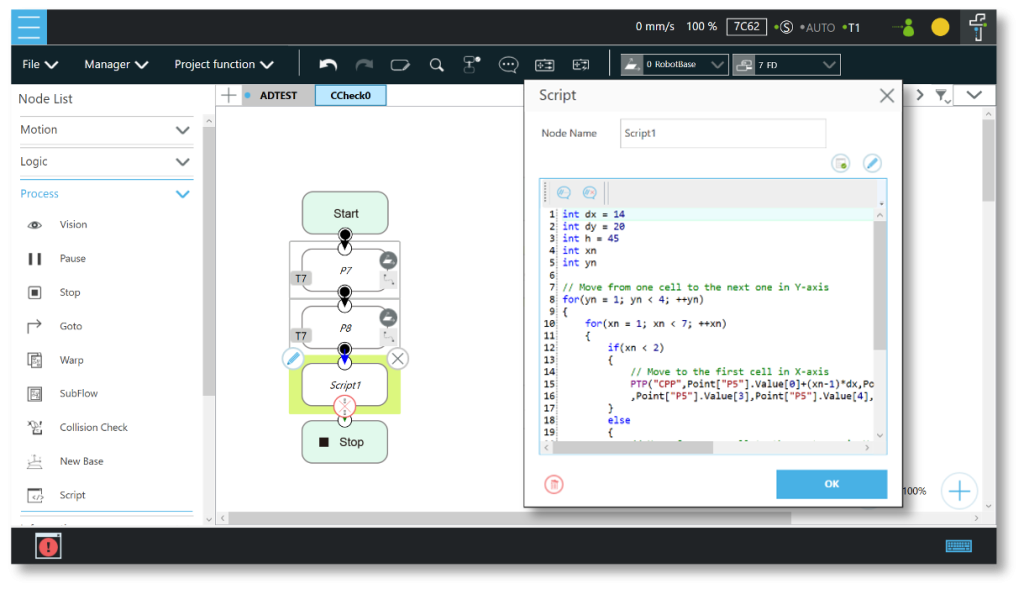

AI Cobot – TMflow 2

- More freedom to program the cobot

- TMflow is a user-friendly software that allows you to create and edit robot tasks through a graphical interface using a series of function nodes, making it easy for first-time users to learn our flow-based programming without any robotics experience.

- If you prefer non-graphical programming, experience a more flexible way to program by using the new Script Node and Script Project.

- The Script feature allows experienced engineers to program with complex logic, and freely edit robot tasks by compiling codes.

- Embrace the method that suits you best and enjoy coding with unparalleled freedom!

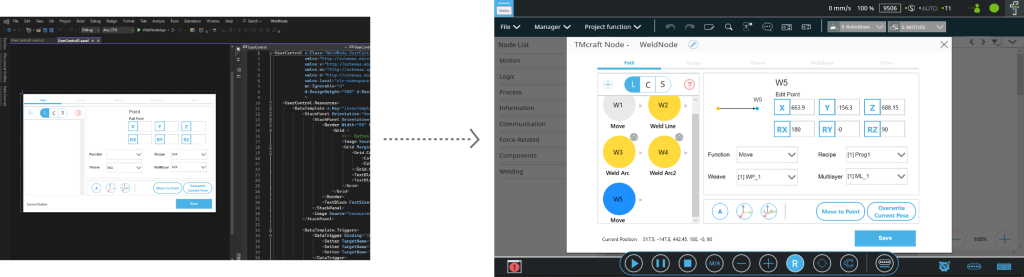

AI Cobot – TMcraft

- Create Personalised Interface with TMcraft for 2nd Development

- TMcraft is a new architecture that allows you to create your own customized UI or background program and embed it onto TMflow, our cobot programming software

- It offers the freedom to develop third-party plug-and-play applications using C# and WPF development

- Additionally, a wizard is available to facilitate the development of high-level applications, such as welding, palletising and sanding, making it easier to customise and create the applications you need

Other Cobots

For more information on collaborative robots available from Australis Engineering click HERE.

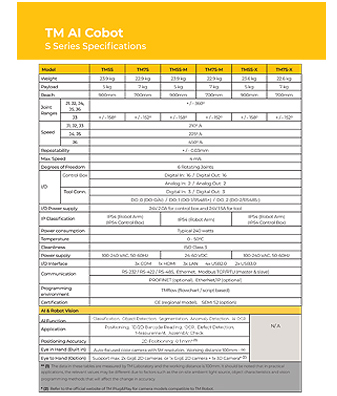

TM25S Specifications

TM Series Cobot Specifications

Video:

The following videos are courtesy of Techman Robot:

TM Series cobot

TM Palletizer Operator

TM exhibiting at Automatica 2023 – featuring TM25S palletising

Techman Robot – Introductory video

Techman’s Full Catalogue

RELATED PRODUCTS