simPAL® Modular Robotic Palletiser

The genius of simPAL®

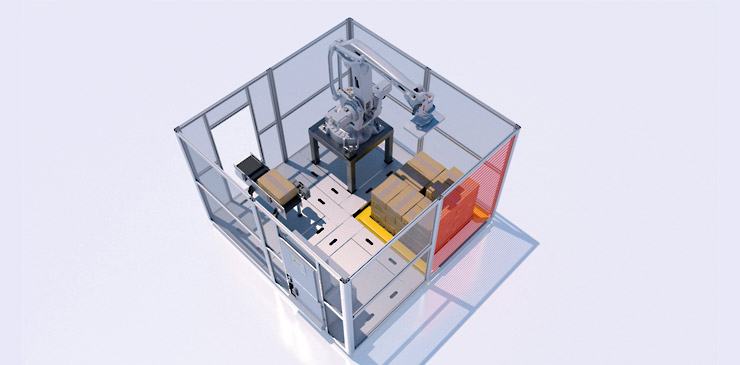

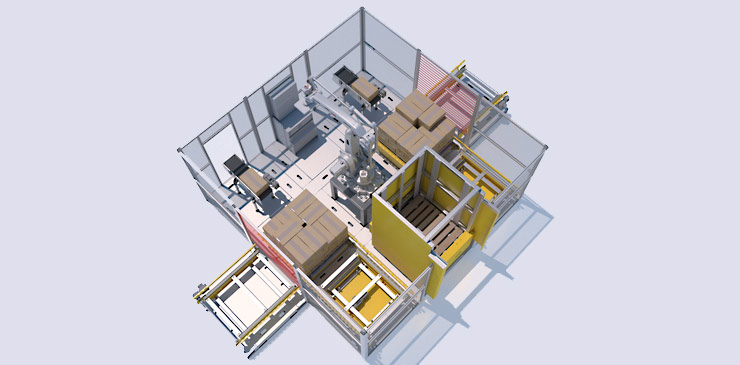

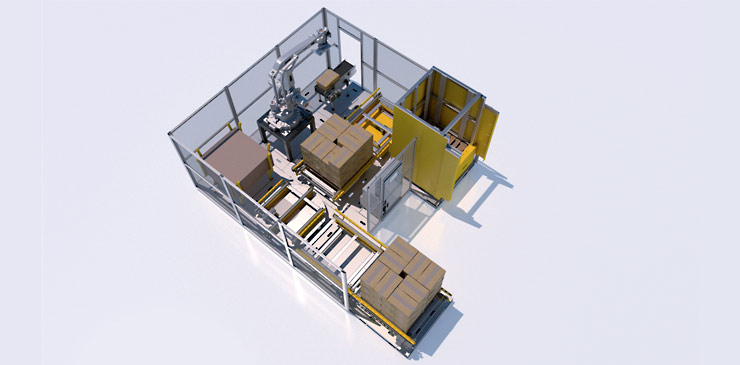

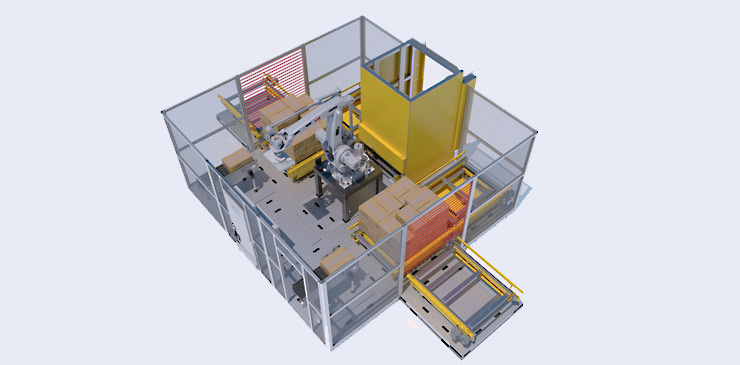

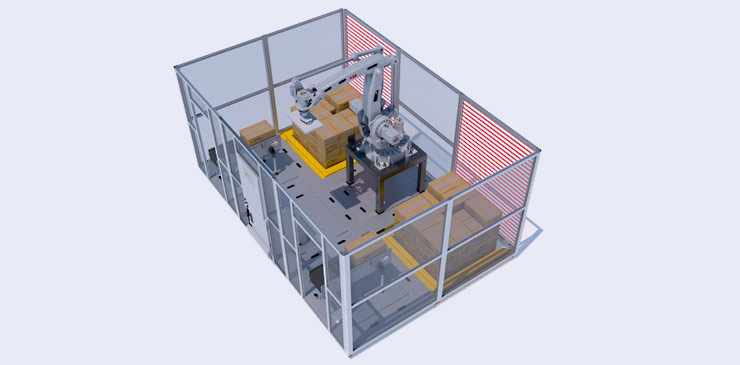

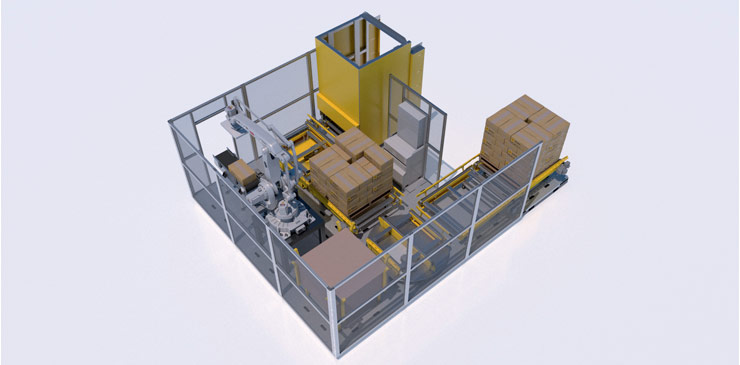

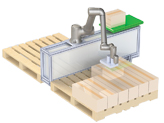

At its core, simPAL® is a robotic palletiser. However the elegance of simPAL is its collaboration of smart software and smart hardware to allow for a highly flexible and modular robotic palletising solution. The success of our system revolves around the use of pre-engineered and pre-wired base “Tiles”. simPAL Tiles can be combined in many different configurations. As production needs change, the same system can be reconfigured and extended by adding additional simPAL Tiles. Due to its modular nature, installation is expedited, reducing downtime and cost.

Faster installation and commissioning

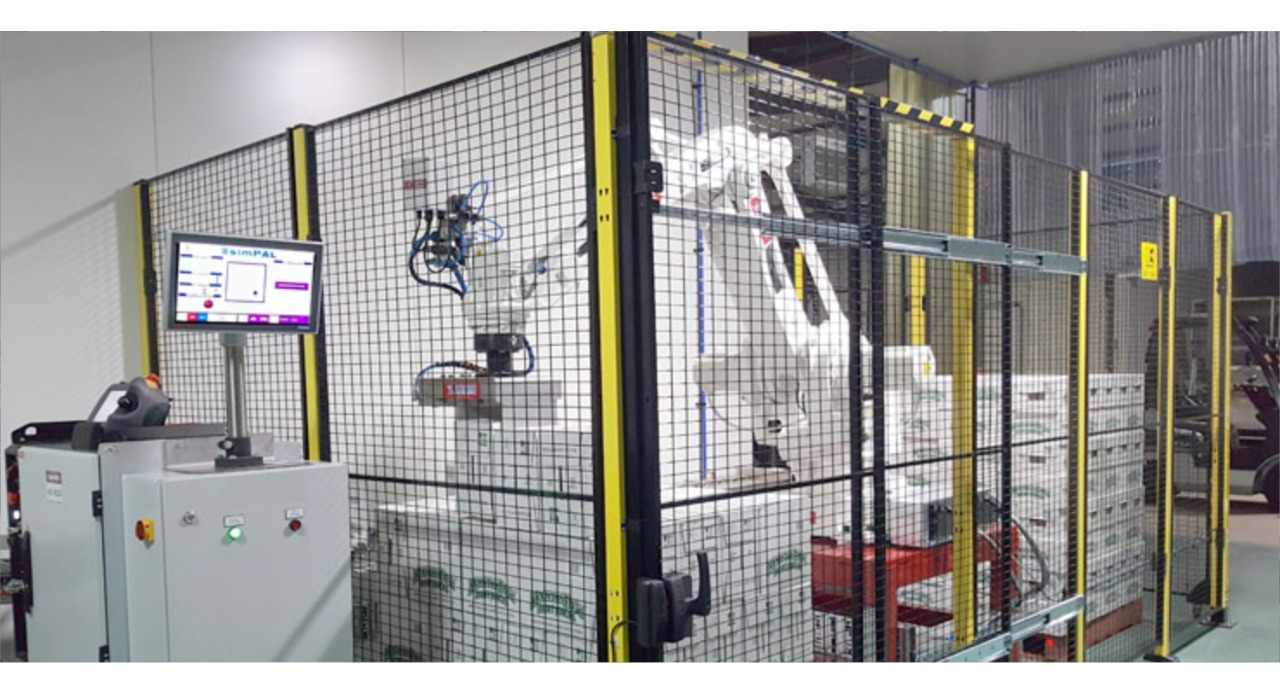

A typical simPAL system can be brought to site, bolted down and connected quickly and easily. Each simPAL Tile includes integrated wiring with quick interconnecting plugs and is self-contained with its own field IO module/s networked to the simPAL Controller for connection of sensors, pneumatics and motor controls. Integrated safety panels connect directly to the Tiles and include normal fence panels as well as access gates, which are safety interlocked. Light curtains or the ABB Safe Move system are other safety options that can be easily integrated with the Tiles. These features mean that your simPAL system can be installed, commissioned and operational much faster than a regular palletiser.

simPAL® Software

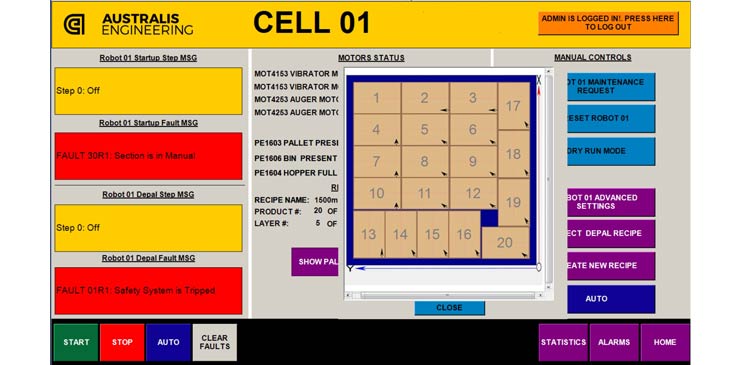

One of the main advantages of a simPAL robotic palletiser is the integration of our proprietary palletising software. Developed over the past 15 years, simPAL software provides long term future proofing benefits. Without the need for complex programming, the user can easily generate new pallet patterns, enter new products and save new recipes. simPAL features an Automatic Pallet Generator that creates an optimised pattern or where there are multiple patterns available, allows the user to choose their preferred option.

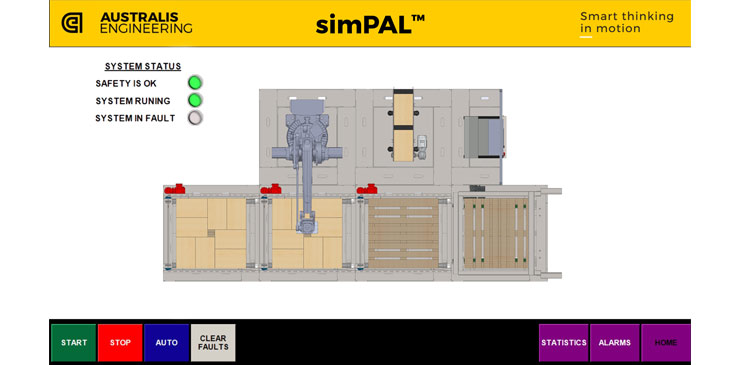

Our software system is supported by a user friendly interface accessed on the control panel by a touch-screen HMI.

simPAL® – a Modular Palletising System

- 10 different modules available that are all connectable and reconfigurable for different palletising layouts

- Each module pre-wired to interconnect modules

- Integrate, proprietary palletising software featuring an Automatic Pallet Generator

- Easy to use HMI touchscreen

- IIOT connected

- Multiple standard grippers available to suit many product types

- Robot capacities from 110kg to 450kg

- Designed to ship inside a standard shipping container

Tailored solutions

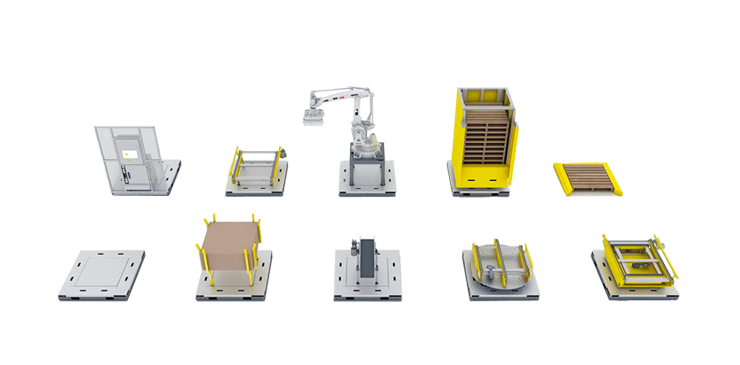

simPAL uses 10 core function Tiles that are used to create a tailored palletising solution. Our 10 Function Tiles are:

- simPAL controller

- Robot and gripper

- Product infeed conveyor

- Pallet conveyor

- Pallet 90 degree transfer

- Pallet turntable

- Pallet layer/slip sheet magazine

- Pallet magazine and destacker

- Pallet floor positioning jig

- Blank tile

By combining any of these tiles in combination, simPAL can achieve 95% of palletising scenarios, including 2 or more pallet positions. The elegance of the simPAL modular palletising system is that it can be easily reconfigured by adding new or re-positioning tile modules. Its modular design also makes it easier to relocate should you reconfigure your production line or move locations.

Applications

A simPAL modular robotic palletising system can be configured for the following applications:

- Palletising cartons or boxes

- Palletising bags or sacks

- Palletising buckets or pails

- Palletising drums

- Freezer palletising

- Cool room palletising

- Dusty environments

Integrated Palletising Systems

Importantly, as materials handling experts, Australis brings its extensive conveyor expertise to all robotic palletiser systems. Other robotics suppliers frequently buy their conveyors from us because they trust us to be able to solve the complexities of synchronising the product pick-up off the conveyors and the removal of a finished pallet of product with the operation of the robot. This is a crucial factor to ensuring your palletising project achieves its maximum return on investment and is a good reason to use a supplier such as Australis.

Contact UssimPAL ® is a Registered Trademark of Australis Engineering Pty Ltd

Click on the case study below to view

Find out more about our Robotic Palletising solutions by reading the following Case Studies:

Cement Australia, Townsville – Robotic bag palletiser system with in feed and out feed conveyors

simPAL® Video:

Introducing our smart, modular, palletising system – simPAL

Other Palletiser videos:

Bag Palletiser: Watch the video of our Robotic Bag Palletiser palletising 20kg bags of cement:

RELATED PRODUCTS