Robotic Palletisers

Robotic Palletiser Solutions

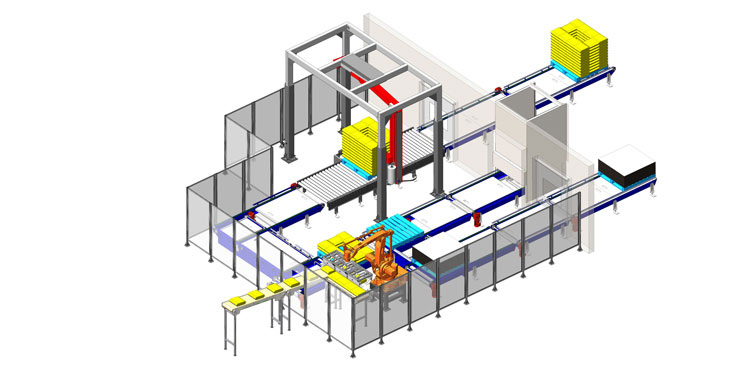

Robotic palletisers are a great choice for high speed, high payload or applications requiring greater flexibility. In most palletising examples, a multi-axis industrial robot used as a robotic palletiser is a clear winner for the right choice for your palletising system. Robotic palletisers can be designed to pick and place from multiple in-feed conveyor lines and to palletise to multiple pallet positions. Our smart designs can also incorporate a tear pad, top sheet or layer sheet if required. An Australis robotic palletising system can be custom designed for cartons, bags, drums or shrink-wrapped products and can provide a range of gripper head options to suit your product and the application.

With a broad range of robotic palletiser, mechanical palletisers and mini palletiser experience, Australis can offer you the right advice for choosing the best type of palletiser for your product, line speed, budget and available area.

While Australis are an authorised ABB Robot value provider and choose ABB robots whenever possible, we have extensive experience with other robot brands as well. If your site has existing brands such as Yaskawa, Kuka or Fanuc, we can also supply and program these robots so you can retain common operating and servicing requirements across your robot fleet.

simPAL® Robotic Palletisers

simPAL® is Australis Engineering’s purpose designed, modular robotic palletising system.

Calling on our decades of palletising experience, simPAL® is a collaboration of smart software and smart hardware to allow for a highly flexible robotic palletising solution. simPAL Tiles can be combined in many different configurations. As production needs change, the same system can be reconfigured and extended by adding additional simPAL Tiles. Due to its modular nature, installation is expedited, reducing downtime and cost.

simPAL is Australis Engineering’s primary robotic palletising solution. To learn more about our simPAL robotic palletiser, click the button below.

To see an explanation and video demonstration of our simPAL® software in action, please CLICK HERE.

Authorised ABB Robotics Value Provider

Australis Engineering are proudly an authorised ABB Robotics Value Provider. Our staff are expertly trained in ABB Robotics solutions and software and can assist with your ABB robotic integration projects.

Australis Engineering are proudly an authorised ABB Robotics Value Provider. Our staff are expertly trained in ABB Robotics solutions and software and can assist with your ABB robotic integration projects.

Integrated conveyors and pallet handling for a truly integrated Robotic Palletising system

Our smart thinking in motion philosophy allows Australis to utilise its extensive conveyor expertise on all of our robotic palletiser systems. Many other robotics and automation suppliers frequently buy their conveyors and pallet handling equipment from Australis because they trust us to be able to solve the complexities of synchronising the product pick-up off the conveyors and the removal of a finished pallet of product with the operation of the robot. This is a crucial factor to ensuring your palletising project achieves its maximum return on investment and is a good reason to use a supplier such as Australis who can provide a turnkey solution without needing a external conveyor expert to assist the process.

Contact UsClick on the case study below to view

Find out more about our Robotic Palletising solutions by reading the following Case Studies:

Cement Australia, Townsville – Robotic bag palletiser system with in feed and out feed conveyors

Bag Palletiser: Watch the video of our Robotic Bag Palletiser palletising 20kg bags of cement:

Carton Palletiser: Due to Client confidentiality, we can only offer you a short video of a robotic palletiser in early stages of factory testing:

RELATED PRODUCTS

PREVIOUS CLIENTS