Mini Linear Palletiser

Mini Linear Palletisers – MLP Series

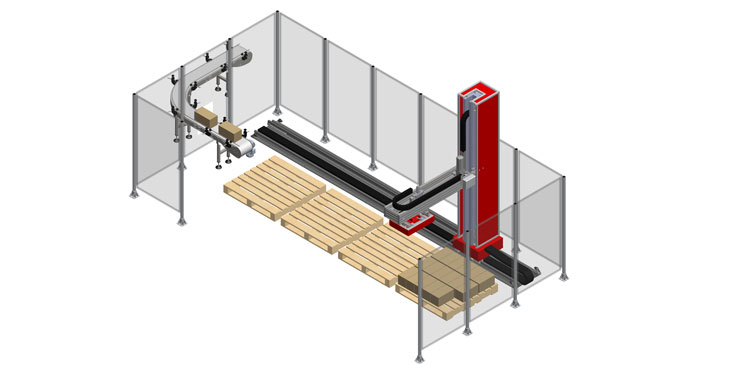

The Mini Palletisers or MLP™ Series are designed and manufactured by Australis Engineering. A Mini Palletiser is an excellent alternative to manual palletising or robotic palletising. They benefit from having a very small foot-print, easy-to-use touch screen HMI, pre-programmed pallet recipes and the ability to palletise cartons, bags and other products with fully customisable gripper heads. The MLP™ series can be fully customised to meet your product type, floor space, height limitations and budget.

Four Mini Palletiser Models Available

The Mini Palletisers are available in four models, meaning there will be an MLP™ that will suit most lower-volume palletising requirements.

- MLP-10™ gantry palletiser

- MLP-12™ single pallet position

- MLP-12™ double pallet position

- MLP-12™ multi pallet positions

The MLP-10 is a gantry palletiser and the MLP-12 is a cantilever arm palletiser. Both variants are capable of palletising up to 35kg and up to 45 cartons per minute (dependent on product size, weight and desired throughput) – however, the ideal weight range is 10kg to 20kg and slightly slower speeds (more weight or speed and a robotic palletiser is advantageous). Both models can also be manufactured with multiple pallet positions which is especially useful for lower throughput production areas that have a high diversity of product types that need to be palletised independently.

Automate your palletising to increase efficiency and reduce OHS problems

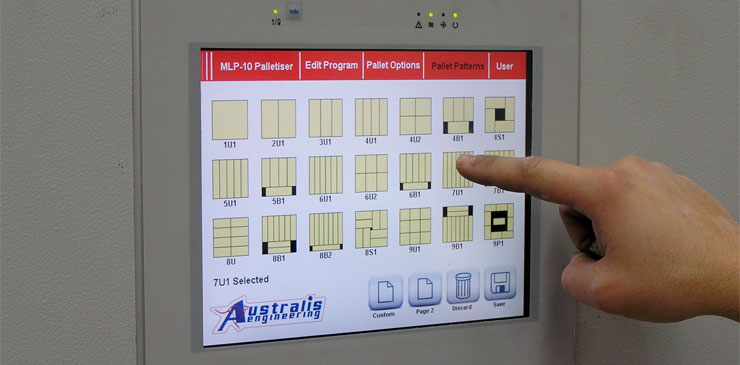

The MLP series can be programmed with standard pallet recipes. Our automation engineers will programme pre-set box and pallet patterns suitable for your products. Once installed, your operators simply use the HMI screen like an iPad to enter the box or bag type and pallet pattern and you are off and running! If your product dimensions or pallet patterns change, we can easily add more ‘recipes’ to your palletiser to help future proof your investment.

Cost effective, proven, reliable palletising

Benefits of the MLP series :

- Easy to use. If you can use an iPad you can operate a Mini Palletiser. How? The MLP’s comes with a pre-programmed touch screen HMI control for easy operator control. Ok – so you will need some training, but once our Automation Engineers have programmed your standard pallet patterns and box sizes, daily operations are very simple thereafter.

- Pre-programmed. Most customers can use the MLP straight away because it comes pre-programmed with your predetermined pallet pattern recipes (we have over 160 patterns to choose from), or we can customise a pallet pattern to meet your specific requirements.

- Ease of Use. Your operator simply types in your box dimensions and selects a pallet pattern and the number of rows per pallet (stack height) and press go. Easy! Watch the video in the Video Tab to see just how simple it can be.

- Handles virtually any carton or bag type. The MLP’s can be fitted with vacuum gripper, plate gripper or bag gripper heads for different products up to 20kg (or more depending on throughput speed). We can offer a single box pick up (the simplest method) or multiple box pick-up if you need to achieve higher palletising rates

- Small footprint. Don’t think you have enough space for a palletiser? The standard single pallet MLP-12 has a footprint of approx 2.4m x 2.5m and the MLP-12 Double pallet only 4.2m x 2.5m and MLP-10 2.1m x 2.5m. We can customise the height of the palletiser to suit most locations.

- Grow with your business. Modular and expandable—units can be combined for higher throughput speeds. The MLP-12 allows for future expansion though a straightforward increase of the base-track.

- Safety is a priority. The MLP series comes standard with safety fencing and light curtains plus a Cat 3 integrated safety system with interlocks and E-Stops.

- Reliable. The MLP’s have proven to be extremely reliable in service, with minimal maintenance and downtime.

- Australian made. We are pleasantly surprised how often we are asked this question, and equally surprised at our customer’s positive reaction to the answer. The MLP series are wholly designed and manufactured in Australia by Australis Engineering.

Customised Palletising Solution

The Mini Linear Palletisers can be easily customised with the following options:

- Multi – pallet positions – single, double, triple, quadruple, quintuple

- Palletise and Wrap (with an integrated automatic or semi-automatic pallet wrapper)

- Extended in-feed conveyors available to suit your requirements

- Automatic product in-feed conveyor

- Multi-line option

- Automatic pallet magazine/ dispenser

- Automatic pallet in-feed and out-feed conveyor

- Carton tape sealer on box in-feed

- Carton labelling or bar coding

- Light Curtains on pallet out-feed

- Customised pallet pattern recipes

- Customised gripper heads

Is the MLP series suitable for my operations?

Since we first designed the MLP series of palletisers in the early 2000’s, the cost of robotic palletiser systems has become much more attainable for most businesses. This has reduced the cost advantage that the MLP series once held compared to a robotic palletiser. But that doesn’t mean that the MLP palletisers are redundant! An MLP palletiser is still a great option under the following circumstances:

- Space. If you have very limited space, an MLP-10 palletiser is an ideal solution as the footprint is much smaller than a robotic palletiser. Its foot print is 2.1 x 2.5m

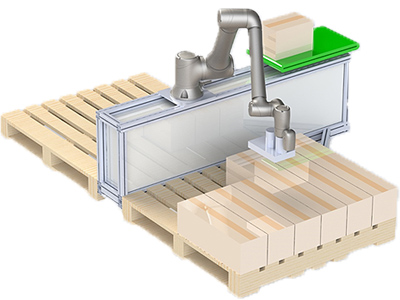

- Product weight. The MLP can be optioned up to a maximum of 35kg, but its sweet spot is in the 10kg to 20kg range. More than this and a robotic palletiser is advantageous. Lower than this and a collaborative robot palletiser is an option worth pursuing.

- Speed. Robotic palletisers are capable of quite high speeds. If you don’t require this, an MLP may be a good option.

Robotic Palletisers

If your operation requires a faster throughput, heavier load or you simply have a preference for a robotic palletiser, our simPAL® modular robotic palletiser could be the solution.

Need more information?

If you need more information about the Mini Linear Palletisers or palletising in general, just click on the Contact Us button below.

Contact UsClick on the case study below to view

Increase Productivity and Reduce Input costs while achieving a demonstrated Return on Investment

Do you need reduce input costs, increase productivity and demonstrate to management a quick and clear return on investment of your Board or Senior Management? The MLP-12 mini palletiser is the solution.

Demonstrated ROI

The following information was provided by one of our Clients who was so impressed that they have now purchase 3x MLP-12’s plus an MLP-10:

By installing an MLP-12 system with integrated stretch wrapper and in-feed conveyor, we have reduced the cost per unit of product produced by 5% overall, including reducing labour by 33% and in the process have removed a WHS manual handling problem and reduced our insurance premiums and payroll tax.

Operations Manager of a major multi-national food manufacturer

Find out more by reading the Case Study: Confidential Client – Mini Linear Palletiser with integrated conveyors, stretch wrapper and safety system

Watch the video of our Mini Palletiser (MLP-12) with 3 pallet positions running at the AusPack 2015 tradeshow. The 3-pallet position option allows multiple product types to be palletised from a single production line in circumstances where multiple products may be produced at any given time.

See the video of the MLP-10 mini palletiser testing carton palletising for a prospective client.

RELATED PRODUCTS

PREVIOUS CLIENTS