Guide Rail Systems

Conveyor Guide Rail Systems

Australis Engineering have been in the business of providing conveyor systems to Australian and International manufacturers since 1983. In that time we have seen, used and designed a lot of Guide Rails Systems for use on our conveyors. The biggest problem with most conventional Guide Rail systems is they are slow to adjust resulting in extended downtime of the line. Conventional Guide Rail systems are manual, meaning on long conveyor lines, the changeover time can be huge, which in turn results in lost production. If you have a conveyor line that is elevated, wall mounted or roof mounted then the change-over time can be a significant contributor to reduced manufacturing efficiency. What’s more, many systems also require multiple change-parts for your various sized products. Based on this extensive conveyor and line control experience, Australis has developed its very own Guide Rail system – the Ezy-Change Mk2 Guide Rail System.

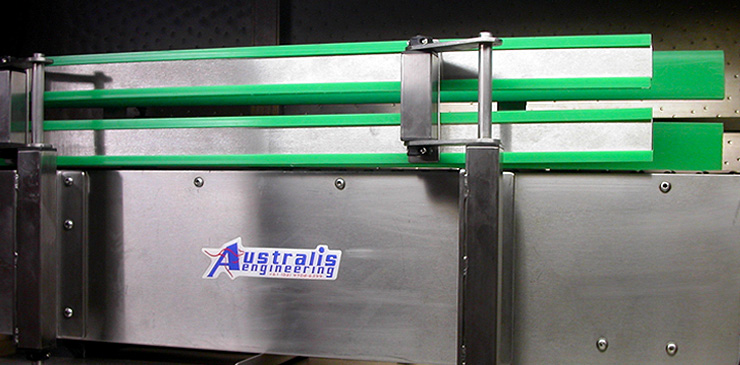

Ezy-Change Mk2 – Adjust a whole line in under 1 minute!

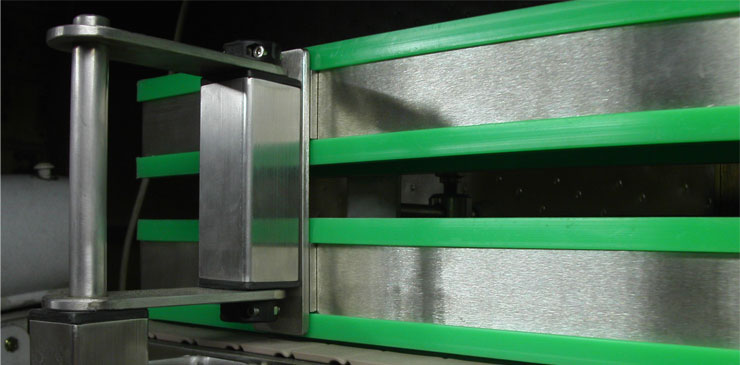

Ezy-Change Mk2 Guide Rails are a semi-automated guide rail system that offer you a fast and easy way to change over an entire production line from a single location and improve your production efficiency. By eliminating the need to change every individual guide rail manually, the Ezy-Change Mk2 Guide Rail System allows changeovers to occur in minutes instead of hours. Clearly this represents a major labour saving, but more importantly means you can recommence production in a shorter time frame.

Benefits of the Ezy-Change Mk2 Guide Rail System

- Semi-automated, guide rail changes from a single point

- Easily retro-fitted to most existing conveyor systems including air, slat or belt conveyors

- Adjustable in increments of less than 1mm

- Electronic or PLC integration as required

- Electronic controls allow for the fast, easy and precise setting of sizes for different product types/ dimensions

- No change parts and no manual adjustment of each guide bracket – adjust a whole line from a single point

- Reduce OHS risk by eliminating high level guide rail adjustment – the EzyChange control panel can be position at ground level, or add PLC integration for automated adjustment based on your differing product sizes

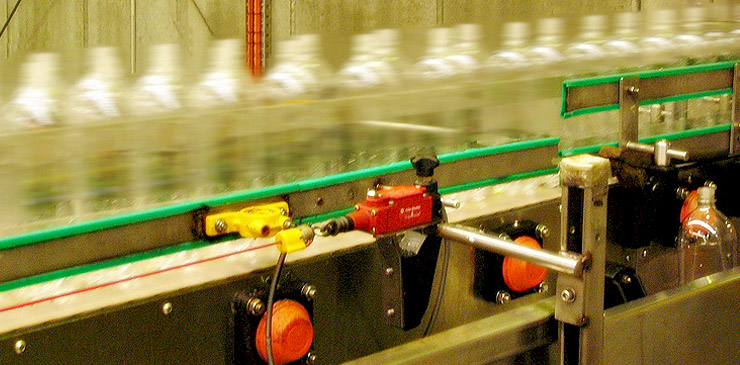

- Suitable for Australis designed Air Conveyors and LowPro Conveyors or virtually any standard conveyor systems

- A manual version is available for the budget conscious user

Do you have a high number of product change-overs per operating shift, or very high through puts that are badly affected by downtime of your production time caused by product changeovers? New in 2015, the Patented, Ezy-Change Automatic Guide Rails can improve your production efficiency.

Click HERE to read more.

Standard / Manual Guide Rails

Don’t need the automation of an Ezy-Change Guide Rail system? Australis can also supply and fit standard, manual style guide rails.

Manual Guide Rails use a mechanical spring mechanism on each guide rail post, allowing you to manually change each guide-post on an entire conveyor line. Manual Guide Rails are ideal when your line operates with infrequent product changeovers.

Our manual guide rails are generally available with an Ultra-High plastic covered stainless steel rail or flat bar, or plain Stainless Steel rails to suit the relevant operating environments and to cater for different product materials (glass, PET, Cardboard, metal etc). We offer Manual Guide Rails with Straight and Curve sections and Fixed or Adjustable brackets.

Contact UsClick on the case study below to view

Find out more by reading the following Case Studies of our projects that feature our Ezy-Change Guide Rail System:

Coming soon…

The following video demonstrates the Ezy-Change Guide Rail system and shows you how easy it is to adjust the guide rails to suit multiple product types.

Click here or on the brochure image to view more information on our various Guide Rail Systems

Click here or on the brochure image to view more information on our various Guide Rail SystemsRELATED PRODUCTS

PREVIOUS CLIENTS